Pintsch bubenzer

The EBH series brakes, designed according to DIN 15435 standards, feature adjustable brake springs, self-lubricating bushings, and high-grade stainless steel components for reliable and low-maintenance operation. Ideal for various industrial applications, the EBH series offers optional features such as automatic wear compensation and weather-resistant coatings, making them suitable for both indoor and outdoor use.

The EBN series brakes are designed according to DIN 15435 standards, featuring adjustable brake springs, self-lubricating bushings, and stainless steel components for long-lasting performance. These brakes are ideal for heavy-duty industrial applications, offering reliable operation with minimal maintenance. Options include automatic wear compensation and weather-resistant coatings for outdoor use, ensuring versatility across various industrial sectors.

The SB 17 MX brakes are designed for precise control and reliability in crane gantries, slewing drives, and smaller hoists. With an electromagnetic release and IP54-rated magnet, these brakes offer high performance and adjustable torque. A built-in rectifier allows direct connection to AC power, while options such as hydraulic damping provide soft braking. Compact and easy to install, the SB 17 MX is ideal for motor-mounted applications requiring efficient, durable braking.

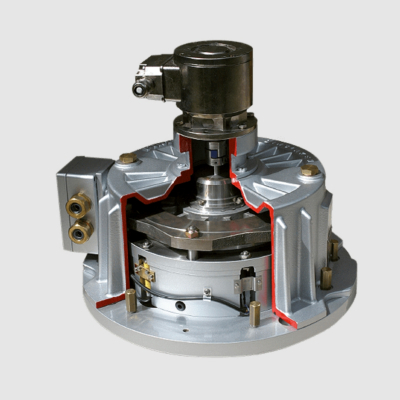

The KFB series spring-applied safety brakes are designed for high-load applications, offering reliable performance in industries like steel mills, wind energy systems, and coal mining. With IP67 seawater protection, these brakes are ideal for harsh environments. The KFB brakes feature a compact design, high wear reserve, and low maintenance requirements. Options include specialized torque, microswitches for wear monitoring, and anti-condensation heaters for use in diverse industrial settings.

The SFB series brakes are designed for safety and reliability in harsh environments, particularly in marine and offshore applications. With a protection class of IP67 and certifications from leading maritime classification societies, these brakes offer superior performance in shipbuilding, wharf crane installations, and industrial sectors such as steel mills. The SFB brakes provide a high wear reserve, simple maintenance, and a powerful magnetic circuit, making them ideal for both dynamic and static applications. Key features include emergency manual release, submersible design, and easy adjustability for long-lasting performance.

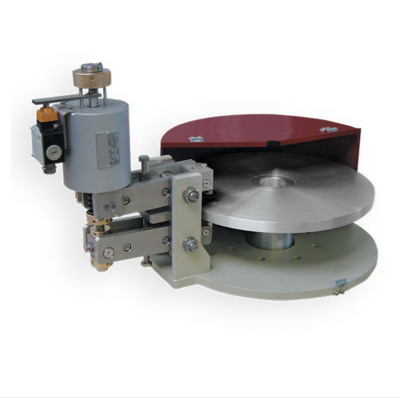

The Pintsch Bubenzer SB 8 Series Electro-Hydraulic Thruster Disc Brake is designed to deliver high performance in compact spaces. Ideal for belt conveyors, it features sintered linings for high friction speeds and organic, non-asbestos linings for low friction speeds. With adjustable brake spring mechanisms, stainless steel components, and maintenance-free bushings, the SB 8 Series offers reliable, long-lasting braking performance. It is suitable for various industrial applications where high precision and durability are critical.

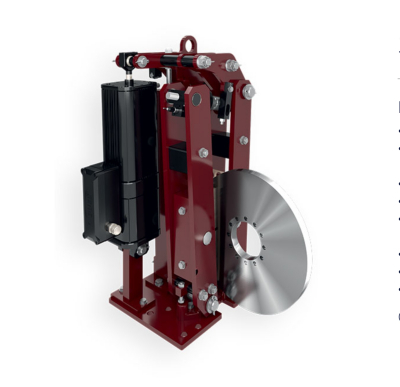

The Pintsch Bubenzer SB 16 with BUEL® Thruster Disc Brake is engineered for demanding industrial environments requiring reliable, high-torque braking performance. With features like automatic wear compensation, adjustable torque, and sintered linings, the SB 16 model ensures precision braking for high and low friction speeds. Its special W-execution offers enhanced anti-corrosion protection, making it suitable for challenging conditions across various industries.

The Pintsch Bubenzer BUEL® SB 28.3 and SB 23.3 Thruster Disc Brakes are designed to deliver reliable and efficient braking solutions for demanding industrial environments. These brakes are ideal for applications in industries such as mining, steel production, and material handling, offering exceptional performance and durability. Featuring advanced technology, the BUEL® series ensures safe and precise braking, meeting the highest industry standards.

Product Catalog