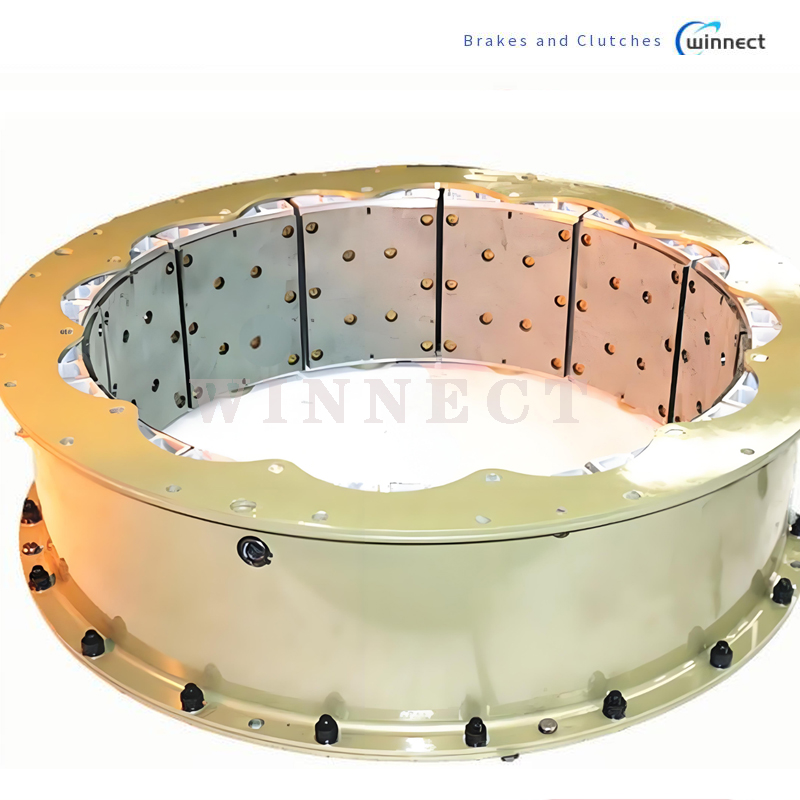

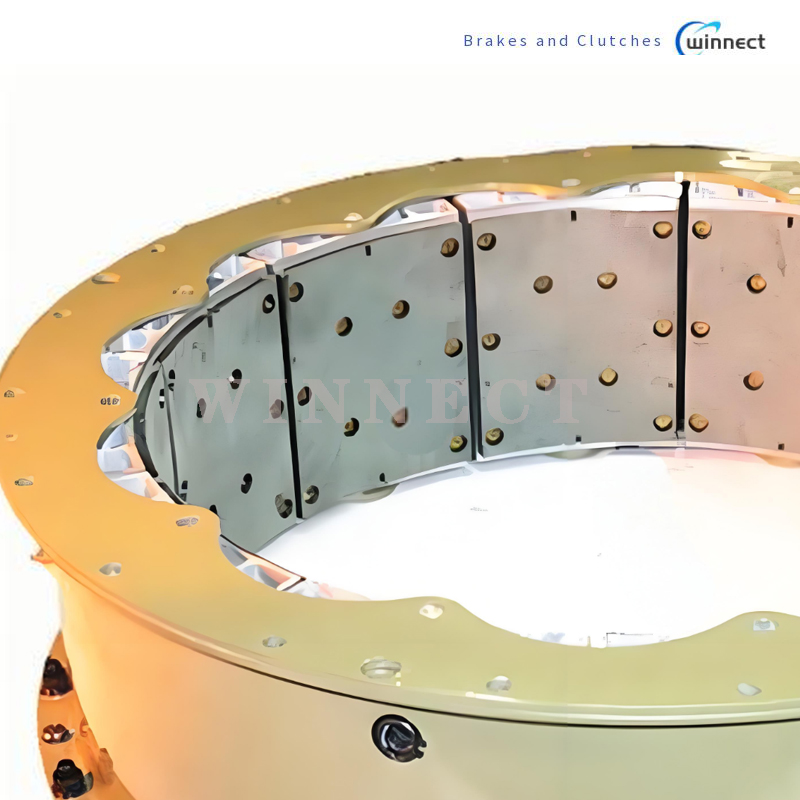

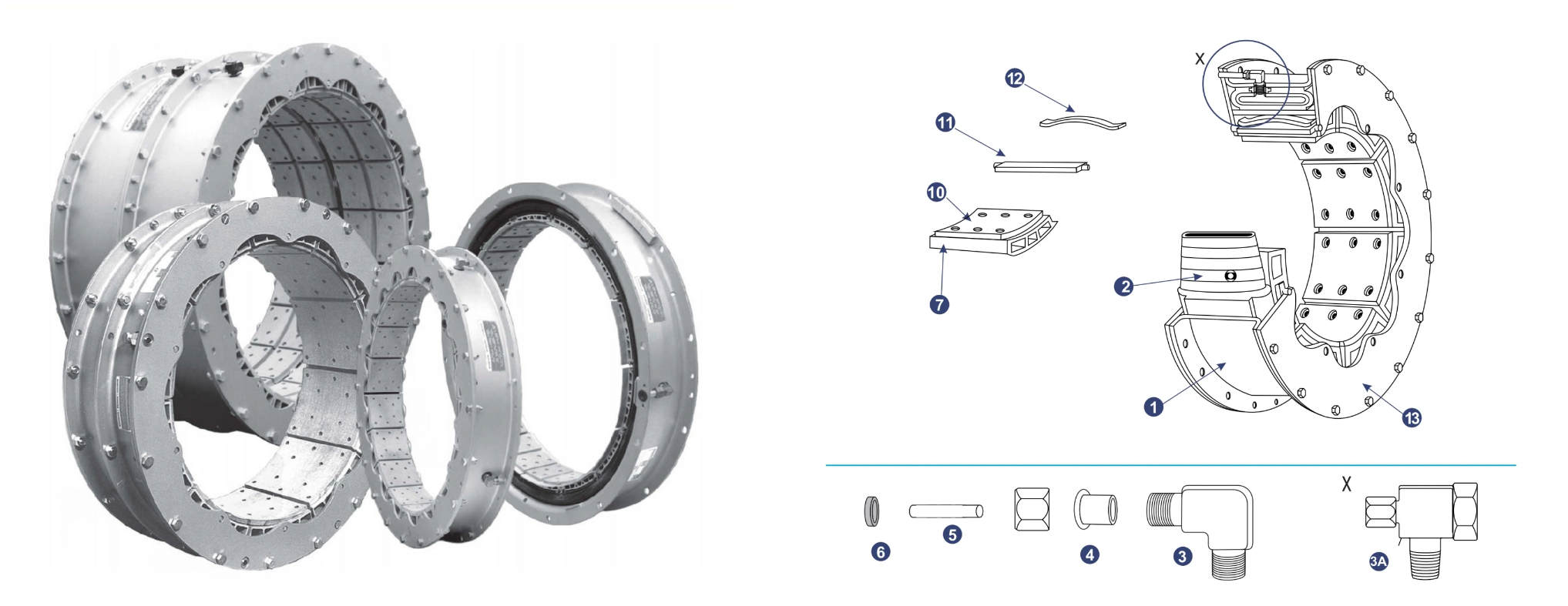

Pneumatic Clutch 38VC1200 42VC1200 46VC1200 52VC1200

Product Description

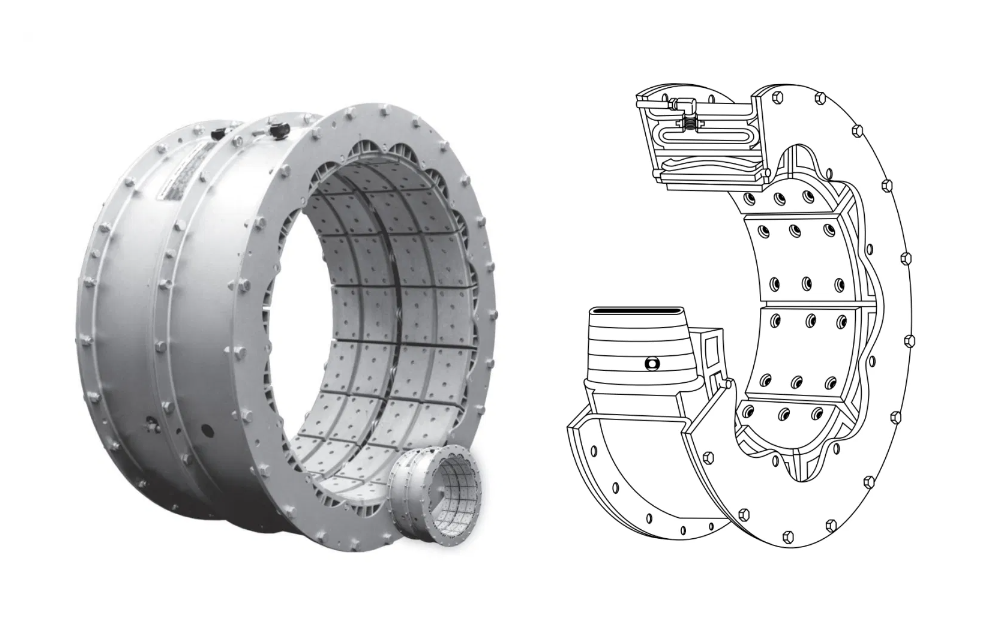

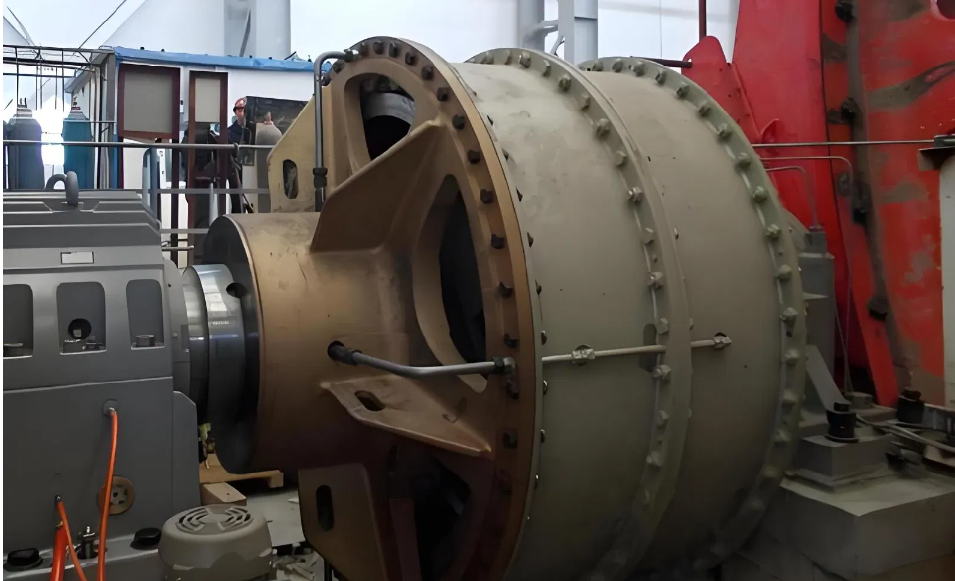

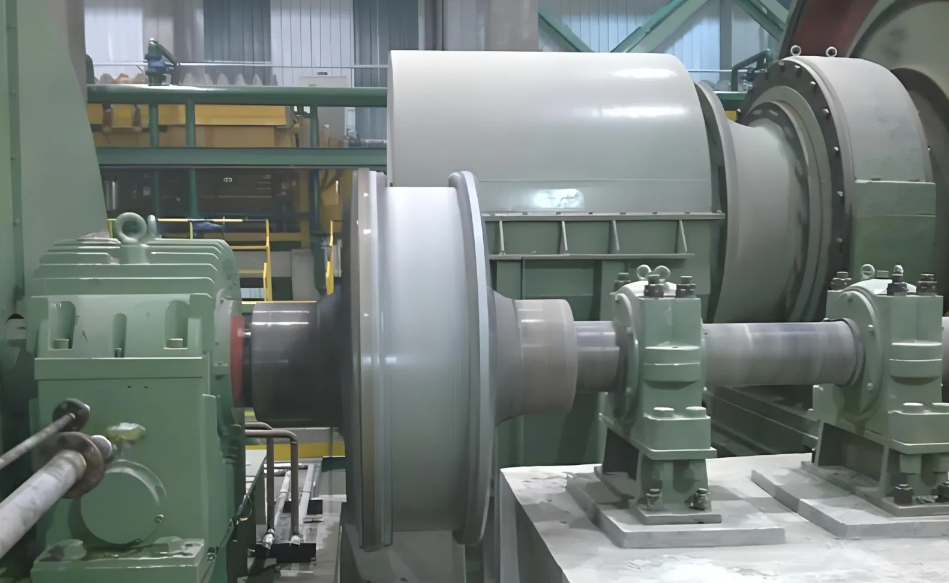

| Air Tube Clutch -Overview The Air Tube Clutch, particularly the VC Element Assembly, is a robust friction clutch designed for severe clutch or brake applications. It is specifically built to handle large inertia loads and sustained slippage, which would typically result in a loss of torque and reduced operating life in conventional clutches. This makes it an essential component in heavy-duty industrial applications such as drilling machinery, watercraft, large mechanical press machines, excavators, ball mills, and rubber machinery. |

Product Advantages

Design and Construction

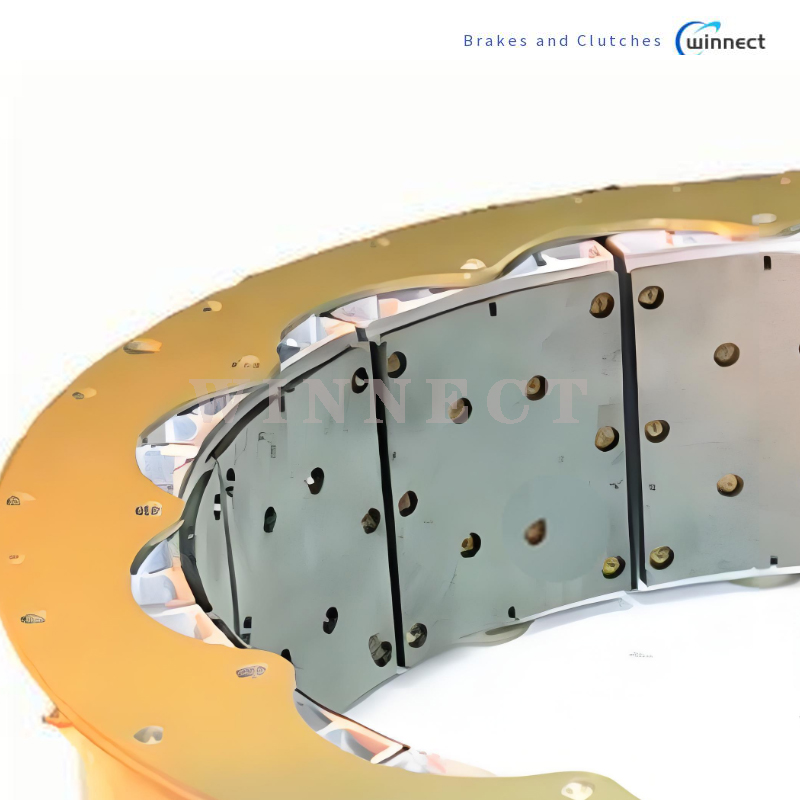

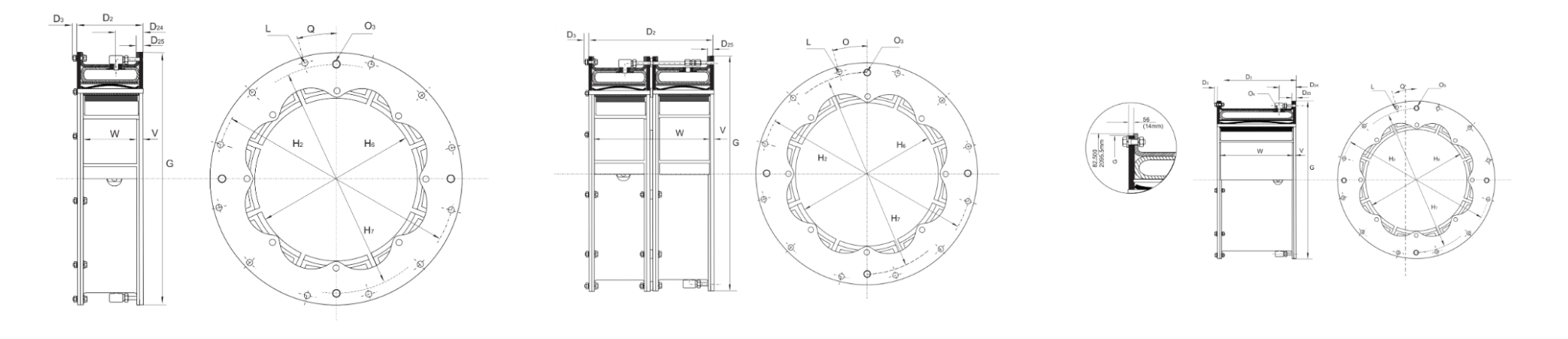

The VC Element Assembly stands out due to its unique design and construction, which differs significantly from CB and CM elements. Key features include:

- Torque Transmission: Unlike CB and CM elements, where torque is transmitted by the sidewalls of the actuating tube, the VC design uses torque bars. These bars pass through cavities in the backing plates of the friction shoes, ensuring efficient torque transmission.

- Replaceable Actuating Tube: The loose actuating tube is contained within a housing formed by a rim and two side plates, making it easily replaceable.

- Friction Shoe Engagement: When the actuating tube is pressurized, it forces the friction shoes to engage around a cylindrical drum, providing a secure and effective engagement.

- Retractable Friction Shoes: Leaf springs in the torque bar cavities retract the friction shoes when the actuating tube pressure is released, ensuring smooth disengagement.

Performance and Specifications

- Torque Capacity: Dependent on applied pressure and rotating speed, with catalog ratings provided at 75 psi (5.2 bar) and zero rpm. The maximum recommended pressure is 125 psi (8.6 bar).

- Size Range: VC elements are available in 24 sizes, identified by the drum diameter (in inches) on which they constrict and the width of their friction lining. For a given drum diameter, two different lining widths are possible, categorized into narrow and wide series.

- Narrow Series Example: 20VC600 (20-inch drum diameter, 6-inch lining width)

- Wide Series Example: 20VC1000 (20-inch drum diameter, 10-inch lining width)

- Drum Diameter: The smallest VC element constricts on an 11.5-inch (292 mm) diameter drum, while the largest constricts on a 76-inch (1930 mm) diameter drum.

Dual Element Capability

Two elements of a narrow series can be bolted together to form a dual element, effectively doubling the torque capacity. Most wide series elements, with the exception of the 14VC1000, can also be dualed. The design constraints of the 14VC1000 element make dualing impractical due to the large drum hub diameter and small drum diameter, which limit the available radial space for mechanical connections.

Product Application:

- Oilfield Machinery: Reliable operation in drilling and extraction equipment.

- Grinding Mills: Efficient torque transmission in milling operations.

- Marine Propulsion: Used in watercraft for propulsion and maneuvering.

- Paper Equipment: Facilitates smooth operation of paper processing machinery.

- Cement Mills: Integral to the functioning of large cement milling machines.

- Large Mechanical Press Machines: Enhances performance and control of press operations.

- Excavators: Delivers high torque for heavy digging and earthmoving tasks.

- Ball Mills: Critical for grinding and milling processes in various industries.

- Rubber Machinery: Ensures precise and powerful operation in rubber processing equipment.

|  |

Product Features

- Large Transmission Torque: Ideal for heavy-duty applications.

- Smooth Operation: Reduces wear and tear on machinery.

- Easy Installation: Minimizes downtime.

- Deflection Compensation: Allows for minor shaft deflection.

- Compact Structure: Saves space and reduces footprint.

- Durability: Long service life and robust construction.

- Sealing: Protects internal components from contaminants.

- Resistance to Deformation: Ensures reliable performance.

- High Material Quality: Withstands heavy use and harsh conditions.

- Low Inertance: Improves response times and operational efficiency.

Product Parameters

VC Clutch Models

| C Clutch Models | Width (inches) | Drum Diameter (inches) |

| 11.5VC500 | 5 | 11.5 |

| 14VC500 | 5 | 14 |

| 16VC500 | 5 | 16 |

| 20VC600 | 6 | 20 |

| 24VC650 | 6.5 | 24 |

| 28VC650 | 6.5 | 28 |

| 33VC650 | 6.5 | 33 |

| 35VC650 | 6.5 | 35 |

| 37VC650 | 6.5 | 37 |

| 42VC650 | 6.5 | 42 |

| 12VC1000 | 10 | 12 |

| 14VC1000 | 10 | 14 |

| 16VC1000 | 10 | 16 |

| 20VC1000 | 10 | 20 |

| 24VC1000 | 10 | 24 |

| 28VC1000 | 10 | 28 |

| 32VC1000 | 10 | 32 |

| 38VC1200 | 12 | 38 |

| 42VC1200 | 12 | 42 |

| 46VC1200 | 12 | 46 |

| 52VC1200 | 12 | 52 |

| 51VC1600 | 16 | 51 |

| 60VC1600 | 16 | 60 |

| 66VC1600 | 16 | 66 |

| 76VC1600 | 16 | 76 |

| 76VC2000 | 20 | 76 |

Common Type Models

| Model | Description |

| LT300/100T | Common Type |

| LT400/125T | Common Type |

| LT500/125T | Common Type |

| LT600/125T | Common Type |

| LT700/135T | Common Type |

| LT700/200T | Common Type |

| LT800/135T | Common Type |

Ventilation Type Models

| Model | Description |

| LT500/200T | Ventilation Type |

| LT500/250T | Ventilation Type |

| LT600/250T | Ventilation Type |

| LT700/250T | Ventilation Type |

| LT800/250T | Ventilation Type |

| LT900/250T | Ventilation Type |

| LT1070/250T | Ventilation Type |

| LT1170/250T | Ventilation Type |

| LT965/305T | Ventilation Type |

| LT1168/305T | Ventilation Type |

| LT1120/300T | Ventilation Type |

| LT1250/300T | Ventilation Type |

Key Features of VC Air Tube Clutch

- Energy Efficiency: Allows motors to start under no load, reducing electricity costs and the load on power grids and substations. Suitable for high-power mills using low-cost, high-efficiency synchronous motors.

- Durability: Designed for harsh conditions such as mining, marine, and oilfields, where high starting loads and sustained engagement typically reduce clutch efficiency and lifespan.

- Radial Constriction and Ventilation: Provides high torque transmission and excellent heat dissipation.

- Eco-Friendly Materials: Uses wear-resistant, non-asbestos friction materials.

- Modular Design: All components are replaceable, making maintenance convenient.

- Automatic Adjustment: Compensates for wear on friction plates and hubs without lubrication.

- Torque Control: Dependent on speed and applied air pressure. By limiting air pressure, the clutch can act as a torque limiting device, providing overload protection.

This comprehensive introduction highlights the versatility, durability, and efficiency of our air tube clutches, ensuring they meet the rigorous demands of various industrial applications.