European Industrial

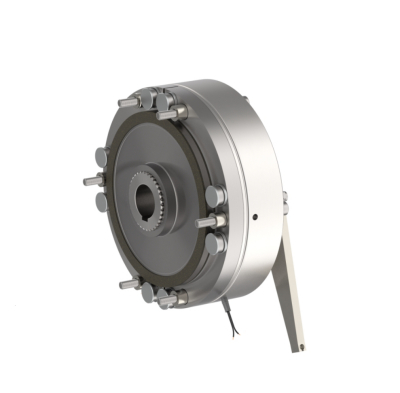

The INTORQ BFK464-R Dual-Circuit Spring-Applied Brake delivers high braking torque in a compact design, making it the ideal solution for applications that require redundancy and safety compliance, such as passenger elevators. This brake features a split armature plate and two independent coil circuits, ensuring adherence to legal safety standards like EN81-20/50-2014 for elevator systems. Its compact size allows for economic installation with minimal space requirements, while the high switching dynamics and long-term stable noise suppression enhance both safety and comfort. With features such as direct rotor-driving shaft connection and low switching noise, the BFK464-R sets a new standard in reliable, economical braking.

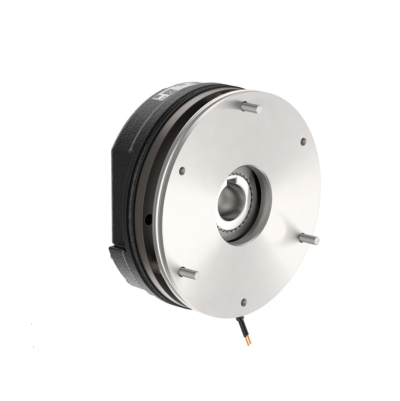

The INTORQ BFK458 Spring-Applied Brake is a highly versatile solution built with a modular system that allows for customization to suit both universal applications and specific industry needs. This all-around brake can be easily configured thanks to its coordinated components, making it suitable for virtually any task. Designed for fast project planning and rapid delivery, the BFK458 features a braking torque range of 1.5Nm to 600Nm, with 9 sizes and multiple models available. Its advanced design includes insulation class F, protection class up to IP55, and optional Cold Climate Version (CCV) for -40°C environments.

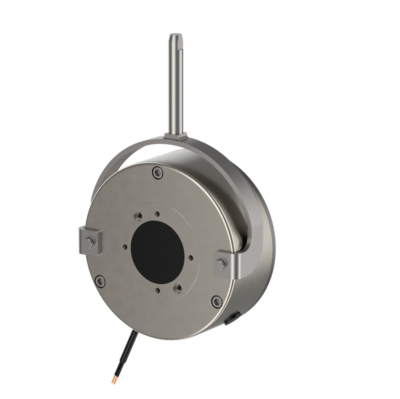

The INTORQ BFK470 Spring-Applied Brake is engineered for reliable performance in the most demanding conditions, including dusty, humid, and extreme temperatures. With a braking torque range of 2 to 370 Nm and IP66 protection, these brakes are ideal for applications such as wind power systems and crane facilities. Its modular design allows for a high degree of versatility and configurability, ensuring you can tailor the brake to meet your specific needs. Optional features like the Cold Climate Version (CCV), hand-release, and noise-reduction make it even more adaptable for tough environments.

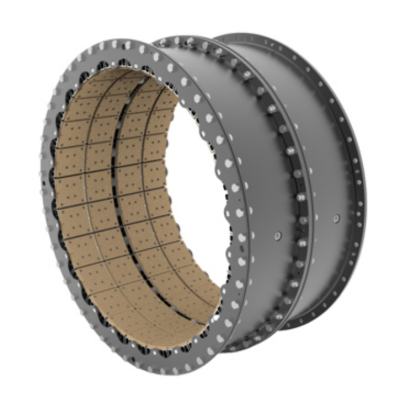

The Danfoss Airflex WCSB Water-Cooled Brake is a high-performance, multiple-disc brake designed for heavy-duty dynamic tensioning, static holding, and emergency stopping applications. With a torque rating of up to 571,119 Nm and a thermal capacity reaching 2,908 kW, the WCSB is a reliable solution for the most demanding environments. This brake is air-applied and features a combination of water- and air-cooling systems, making it ideal for industries such as drawworks, mooring systems, and log yarders.

The Danfoss Airflex WCBD3 Water-Cooled Brake is a third-generation dynamic disc brake designed for high-energy tensioning and static holding in demanding industries such as drawworks, mooring winches, dynamometers, paper mills, and steel service centers. With a torque range of 3,331 to 133,322 Nm and thermal capacity of 750 to 2,980 kW, the WCBD3 offers unparalleled performance and durability. Its dual-piston design and enhanced water-flow dynamics ensure rapid heat dissipation, allowing for optimal functionality in high-energy environments.

The Danfoss Airflex CB Series Constricting Clutches & Brakes are designed for both clutch and brake applications in high-speed, cyclic operations and general power transmission tasks. With a torque range of 41 to 29,400 Nm at 5.2 bar, and a maximum speed of 1,800 rpm, these units are ideal for industries such as can-making, metal forming, printing, commercial laundry, and rubber processing. The torsional resilience of the CB Series allows for flexibility in accommodating minor shaft misalignments, making them an excellent choice for demanding industrial machinery.

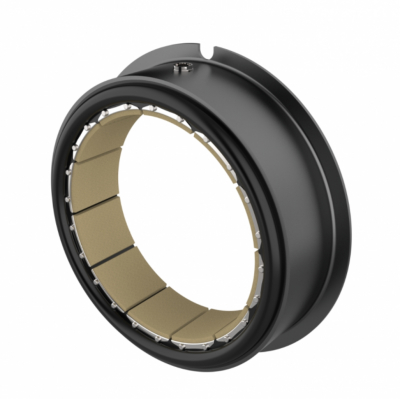

The Danfoss Airflex CM Series Constricting Clutches & Brakes are specifically designed to meet the rigorous demands of the marine industry. These pneumatically actuated drum-style clutches and brakes are ideal for use in diesel-driven, reverse-reduction gears, providing exceptional performance for marine propulsion systems. The ventilated friction shoes allow for moderate slippage during low-energy vessel maneuvering, while ensuring effective cycling engagements during high-energy operations. The CM Series is built to deliver torque capacities ranging from 14,920 to 69,360 Nm, making it a reliable solution for demanding maritime environments.

The Danfoss Airflex VC Series Constricting Clutches & Brakes are designed to handle the most severe clutching and braking applications. Ideal for high-inertia loads and continuous slippage conditions, these air-applied constricting clutches and brakes are commonly used in industries like mining, marine propulsion, metal forming, and oil and gas. The ventilated open construction rapidly dissipates heat, providing high torque capacities of up to 1,706,629 Nm (15,189,000 lb-in), making them perfect for heavy-duty operations that demand shock-free engagement and sustained durability.

The WPT Pilotless® Mechanical Power Take-Off (PTO) is a rugged and reliable solution engineered for heavy-duty industrial applications, including wood chippers, rock crushers, asphalt grinders, pavement milling machines, water blasters, irrigation pumps, and paver units. Designed to meet the demands of modern industrial machinery, the Pilotless® Mechanical PTO eliminates the need for a pilot bearing, improving side load capacity and reducing maintenance costs. Its innovative design simplifies installation, increases uptime, and extends the life of engine main bearings, making it a highly efficient and cost-effective choice.

The WPT Water Cooled Brake (WCB) is a robust solution designed for high-energy absorbing applications where continuous slip is required, such as drawworks, mooring winches, dynamometers, paper converting machinery, uncoilers, and yarders. Featuring copper alloy wear plates and internal water passages for optimal heat dissipation, the WCB offers durability and efficiency for heavy-duty industrial settings. Available with hydraulic or pneumatic actuation, the WCB is highly versatile and comes with multiple configurations to suit various applications.

Product Catalog