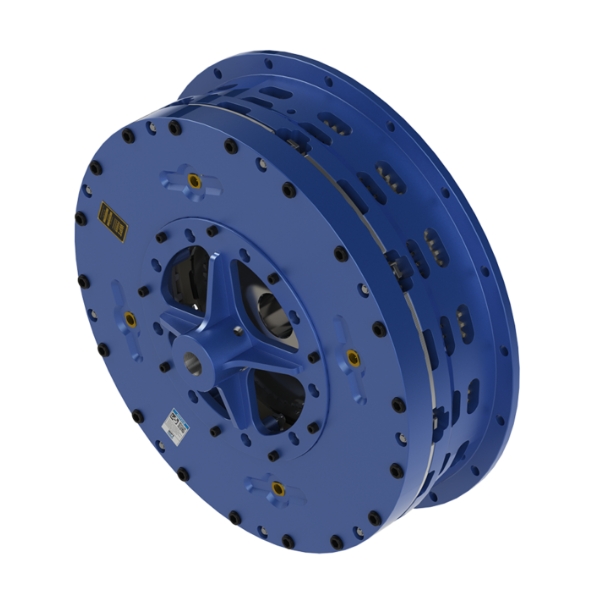

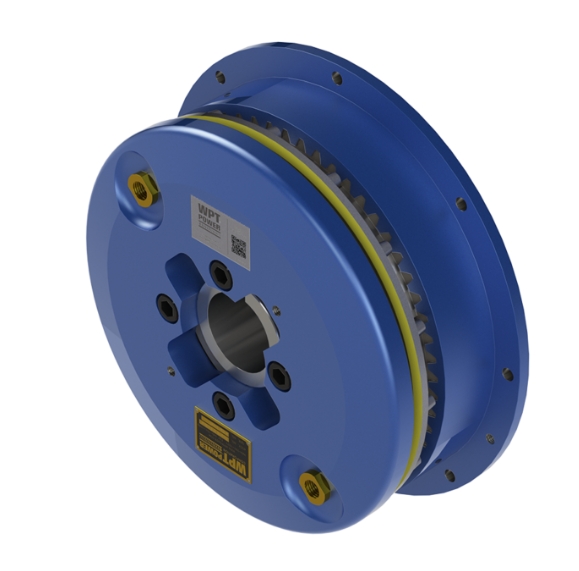

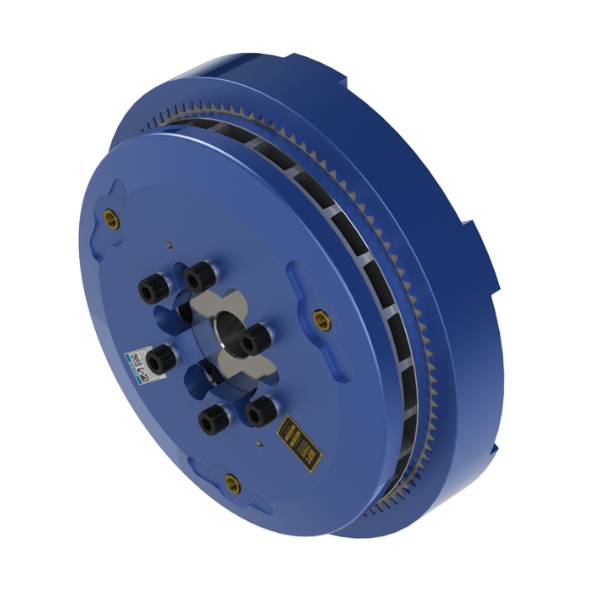

WPT Pilotless® Mechanical PTO Clutches

Product Details:

Pilotless Design for Improved Performance

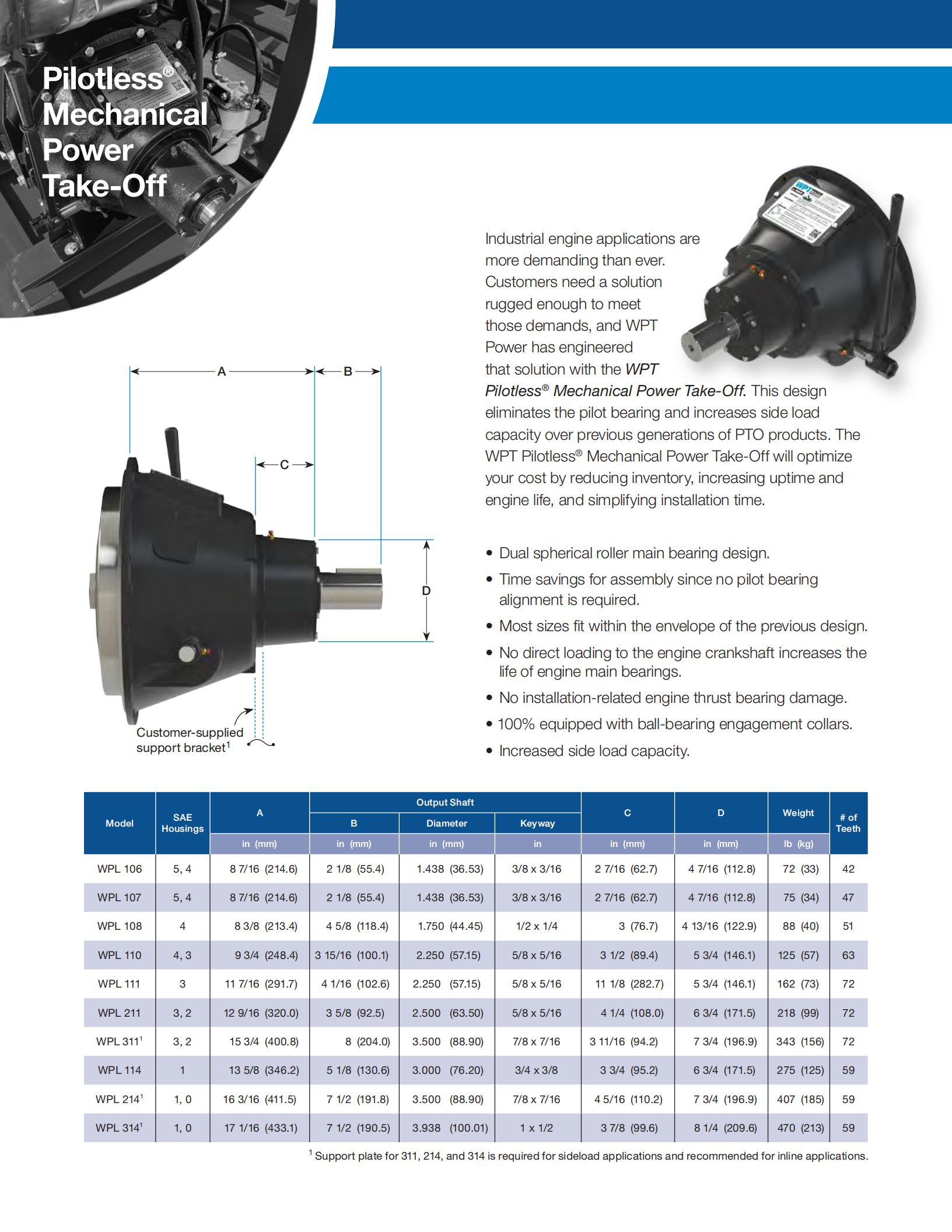

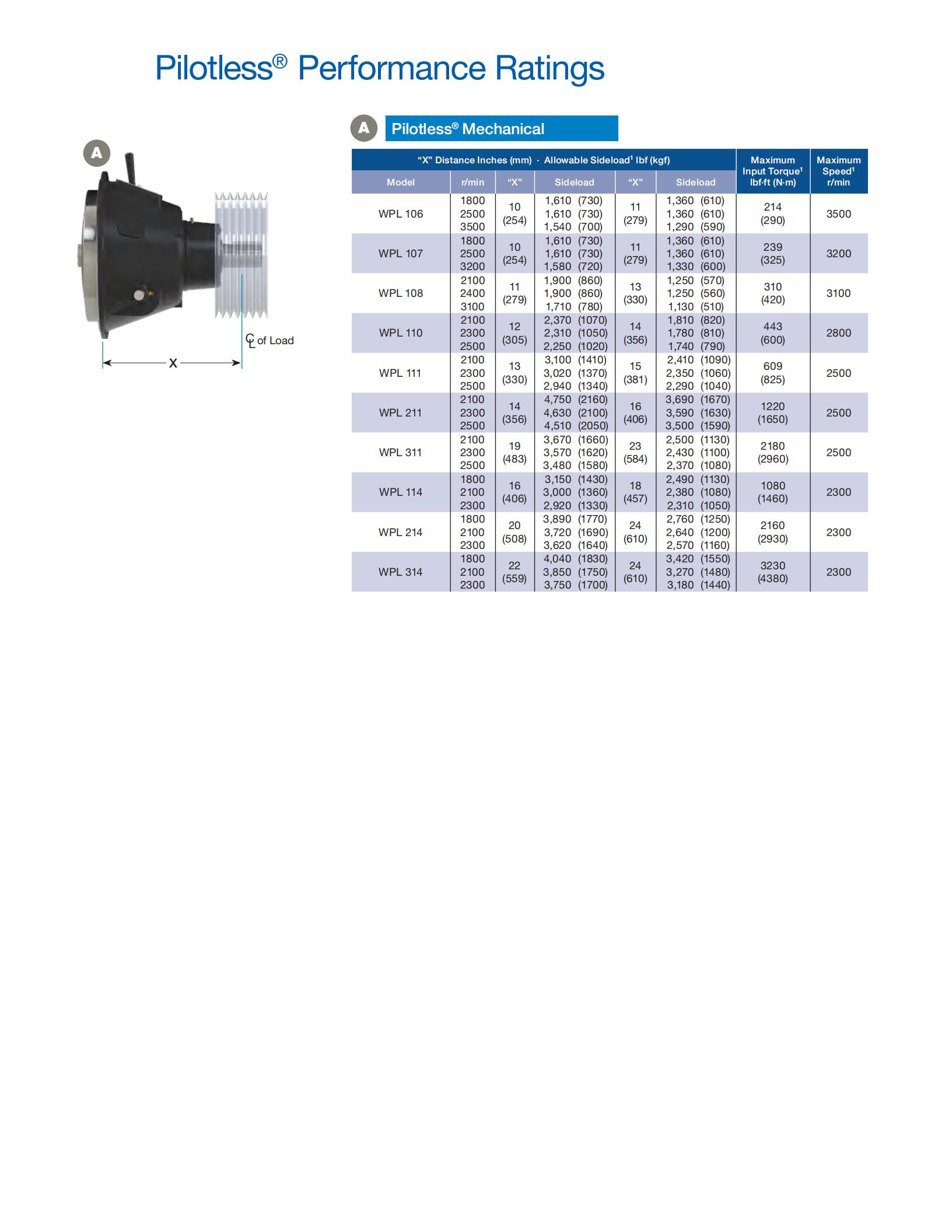

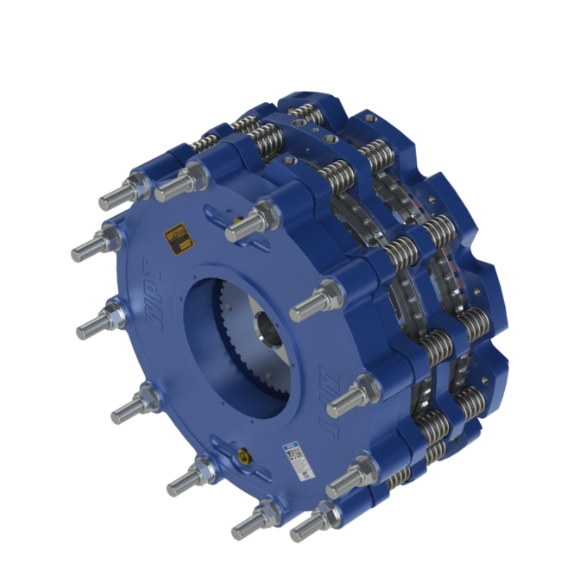

The Pilotless® Mechanical PTO eliminates the pilot bearing, which allows for more efficient operation and longer service life. The unique dual spherical roller bearing design enhances the system’s capacity to handle high side loads and eliminates direct loading to the engine’s crankshaft, thereby extending the life of the engine's main bearings.Increased Side Load Capacity

The design of the Pilotless PTO provides up to 70% more side load capacity than previous generations of PTO products. This makes it ideal for applications that exert heavy side loads, ensuring that your equipment performs efficiently even in the most demanding conditions.Easy Installation and Maintenance

The simplified assembly process of the Pilotless PTO saves valuable time, as it does not require pilot bearing alignment. With no direct loading to the crankshaft, this system also prevents installation-related damage to the engine’s thrust bearing, further increasing its reliability.Fits within Existing Equipment Envelopes

Most sizes of the WPT Pilotless® Mechanical PTO are designed to fit within the envelope of previous PTO models, making it a versatile and adaptable option for equipment upgrades and retrofits.Enhanced Engine Life and Reduced Inventory

The optimized design of the Pilotless PTO helps reduce engine wear, increase uptime, and extend the life of the engine’s main bearings. By reducing the number of components, the Pilotless PTO also helps lower inventory costs and simplifies maintenance.Multiple Friction Options Available

The Pilotless PTO is available with Standard, HD Molded, and HD Laminated friction options, allowing you to choose the configuration that best meets the demands of your application.

Key Features:

- Pilotless design for reduced wear and longer engine life

- Dual spherical roller main bearings for improved side load handling

- No pilot bearing alignment required, saving time during installation

- Up to 70% increase in side load capacity for demanding applications

- No direct loading to crankshaft, protecting the engine's main bearings

- Available with Standard, HD Molded, and HD Laminated friction options

- 100% ball-bearing engagement collars for enhanced reliability

Applications:

The WPT Pilotless® Mechanical PTO is designed for heavy-duty industrial and construction equipment, including:

- Wood chippers

- Rock crushers

- Asphalt grinders

- Pavement milling machines

- Water blasters

- Irrigation pumps

- Paver units