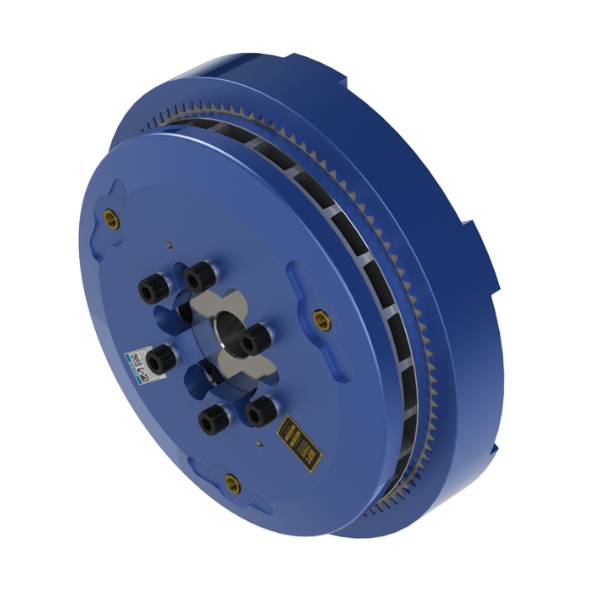

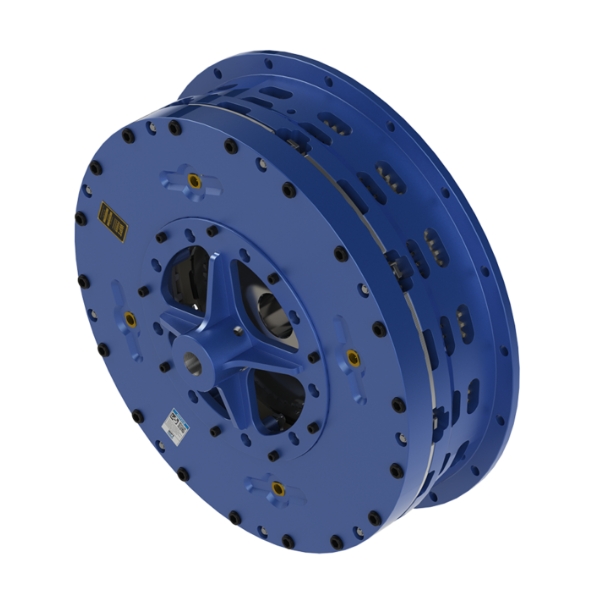

WPT Power Low Inertia Clutch (LIC)

Product Details:

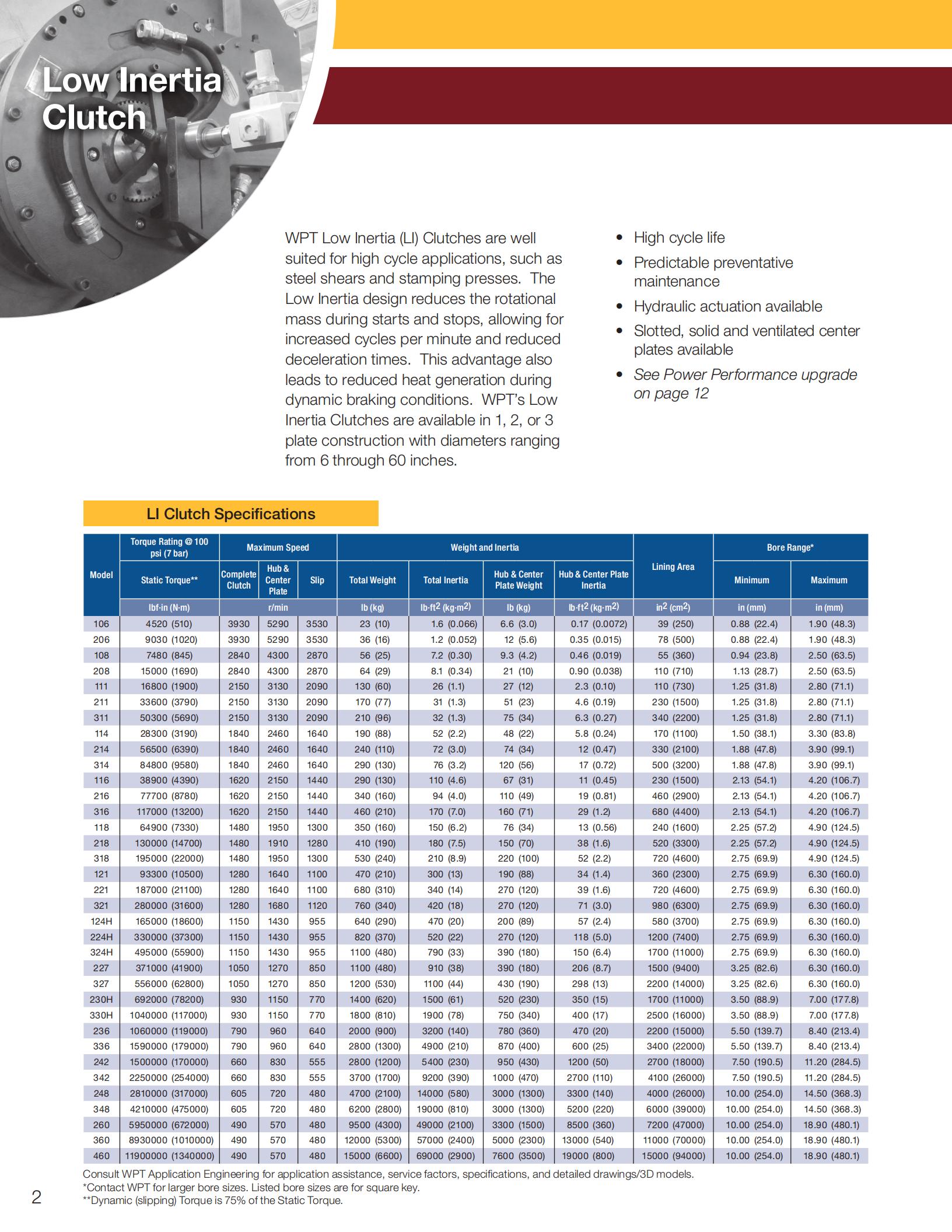

Optimized for High-Cycle Applications

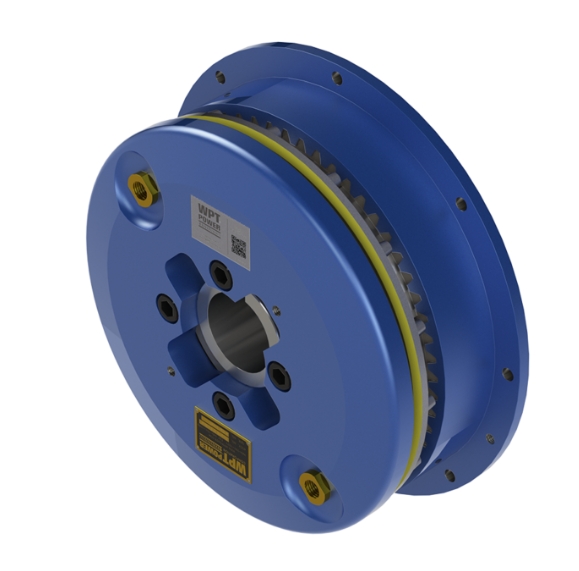

The Low Inertia Clutch (LIC) is ideal for high-cycle operations where rapid starts and stops are essential, such as in steel shears, stamping presses, and other machinery that requires precision timing and frequent cycling. The reduced inertia design significantly improves cycle speed, contributing to increased production output.Reduced Rotational Mass for Faster Cycles

By reducing the rotational mass during starts and stops, the LIC enhances machine efficiency, allowing for more cycles per minute. This translates to faster operation and reduced deceleration times, which helps to minimize energy losses and optimize machine performance.Lower Heat Generation

The low inertia design also helps to reduce heat generation during dynamic braking conditions, extending the life of the clutch and associated machinery components. This makes the LIC ideal for operations where continuous cycling could otherwise cause overheating or excessive wear.Multiple Plate Options

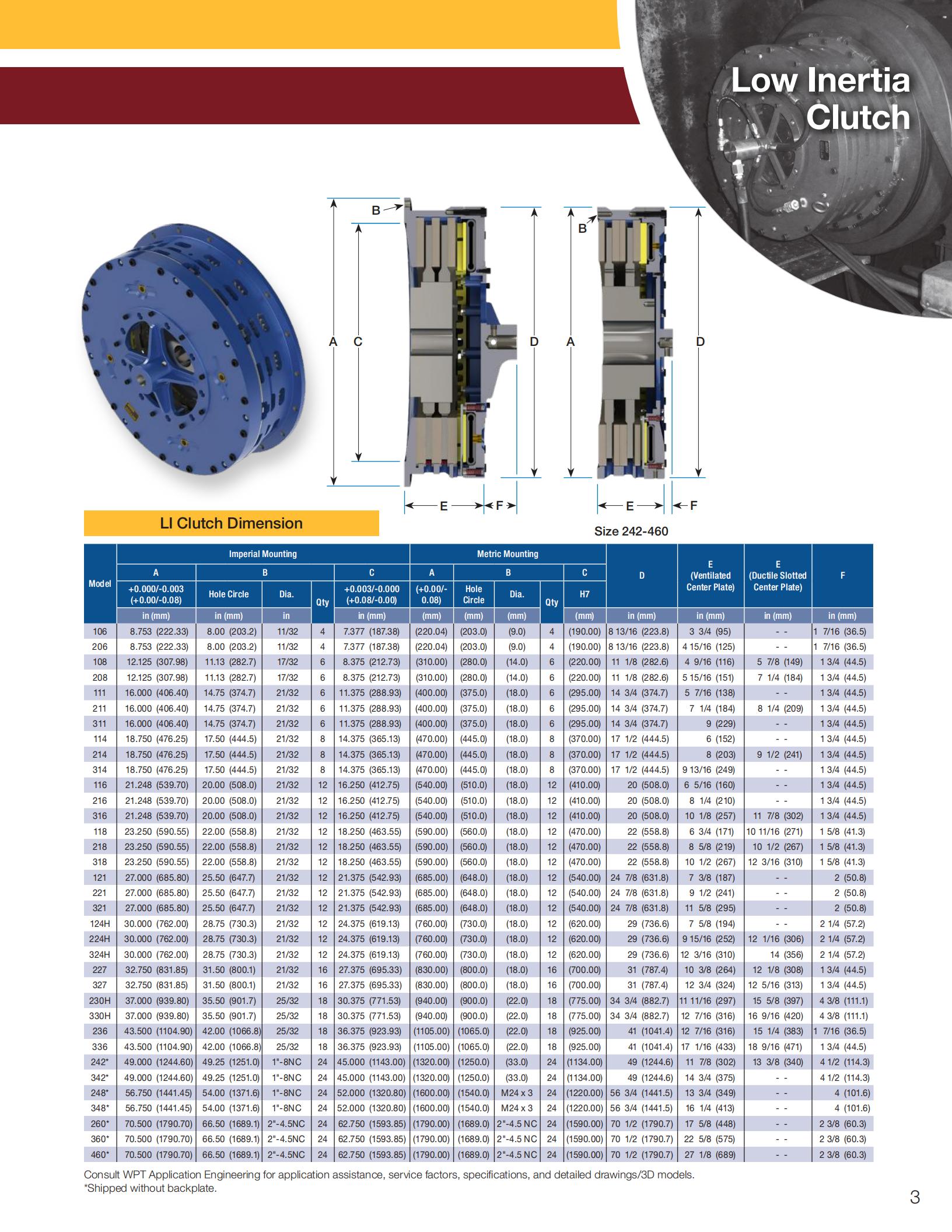

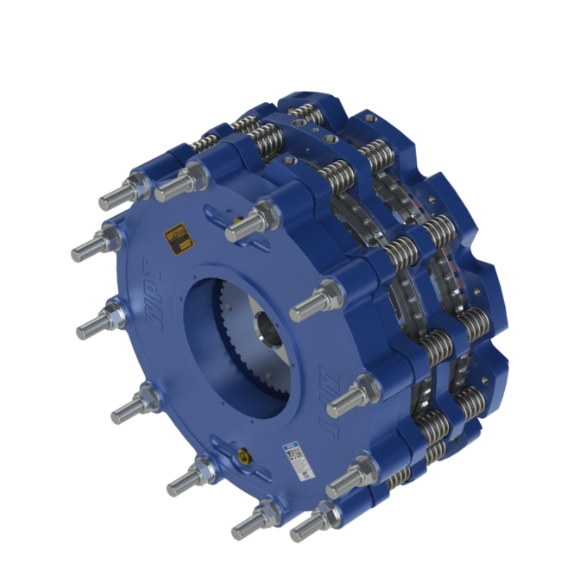

The Low Inertia Clutch is available in 1, 2, or 3 plate construction, depending on the application’s power and torque requirements. Center plates are available in solid, slotted, or ventilated designs, giving operators more flexibility to tailor the clutch to specific operational needs.Predictable Preventive Maintenance

The LIC is designed with predictable preventive maintenance schedules in mind, reducing the chances of unexpected downtimes. This feature helps maintain a consistent level of performance and ensures long-term operational reliability.Hydraulic or Pneumatic Actuation

The WPT Low Inertia Clutch can be actuated using either hydraulic or pneumatic systems, providing adaptability for different operational settings. This allows users to optimize the clutch’s engagement based on their specific system requirements.Marine Corrosion Protection Available

For marine applications, the LIC is available with a Full Marine Corrosion Protection package, ensuring the clutch’s durability even in harsh, saltwater environments.

Key Features:

- Increased cycles per minute with reduced rotational mass

- Minimized heat generation during braking conditions

- Predictable preventive maintenance for reduced downtime

- Available with hydraulic or pneumatic actuation

- Multiple plate options: solid, slotted, or ventilated center plates

- Full Marine Corrosion Protection package for marine environments

- Compatible with the Power Performance LI upgrade

Applications:

The WPT Low Inertia Clutch is ideal for high-speed and precision applications, including:

- Steel shears

- Stamping presses

- High-cycle machinery

- Marine applications

- Dynamic braking systems

- Mining and industrial machinery