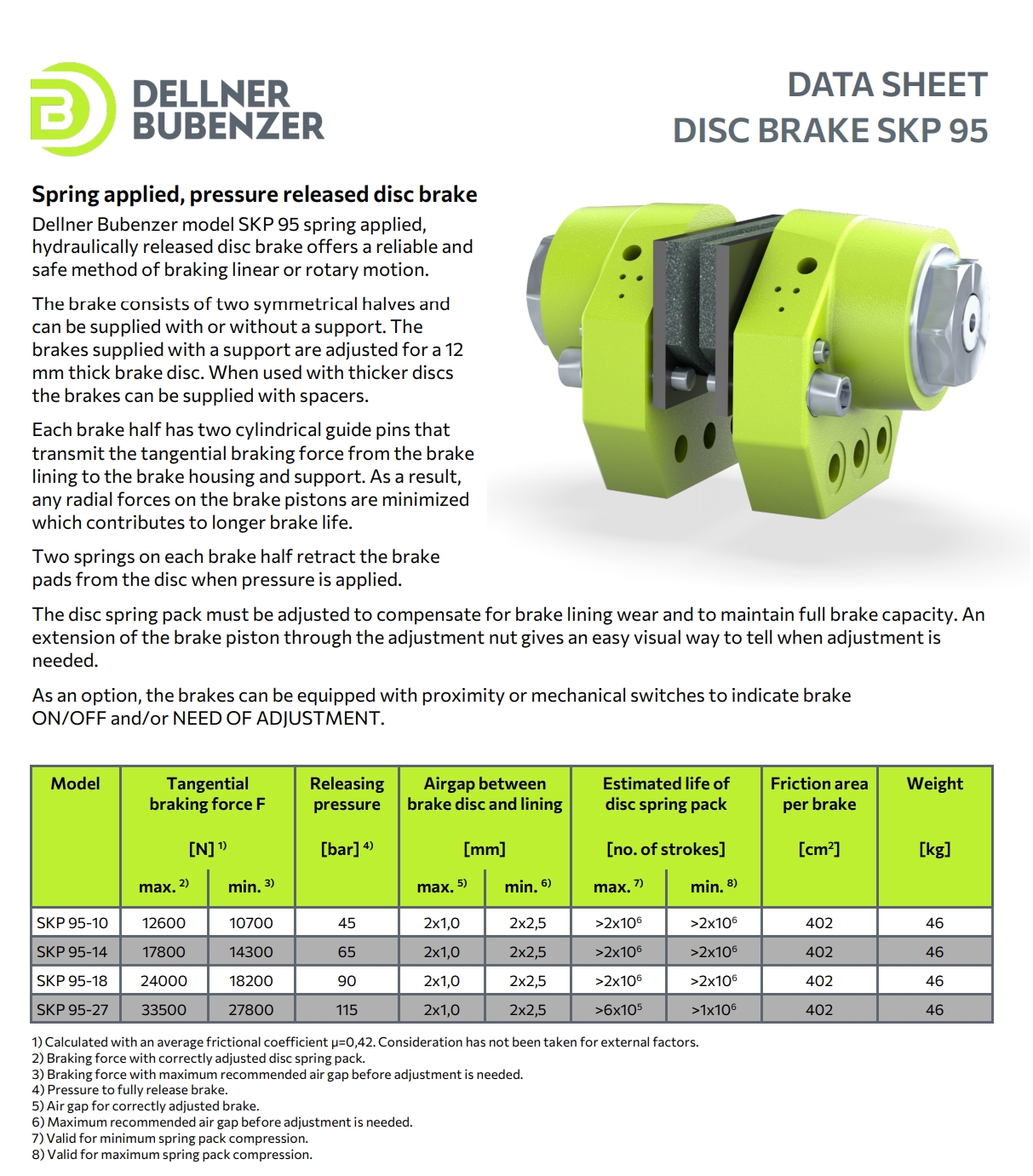

Dellner Bubenzer SKP 95 Fail-Safe Spring-Applied Disc Brake

Product Details:

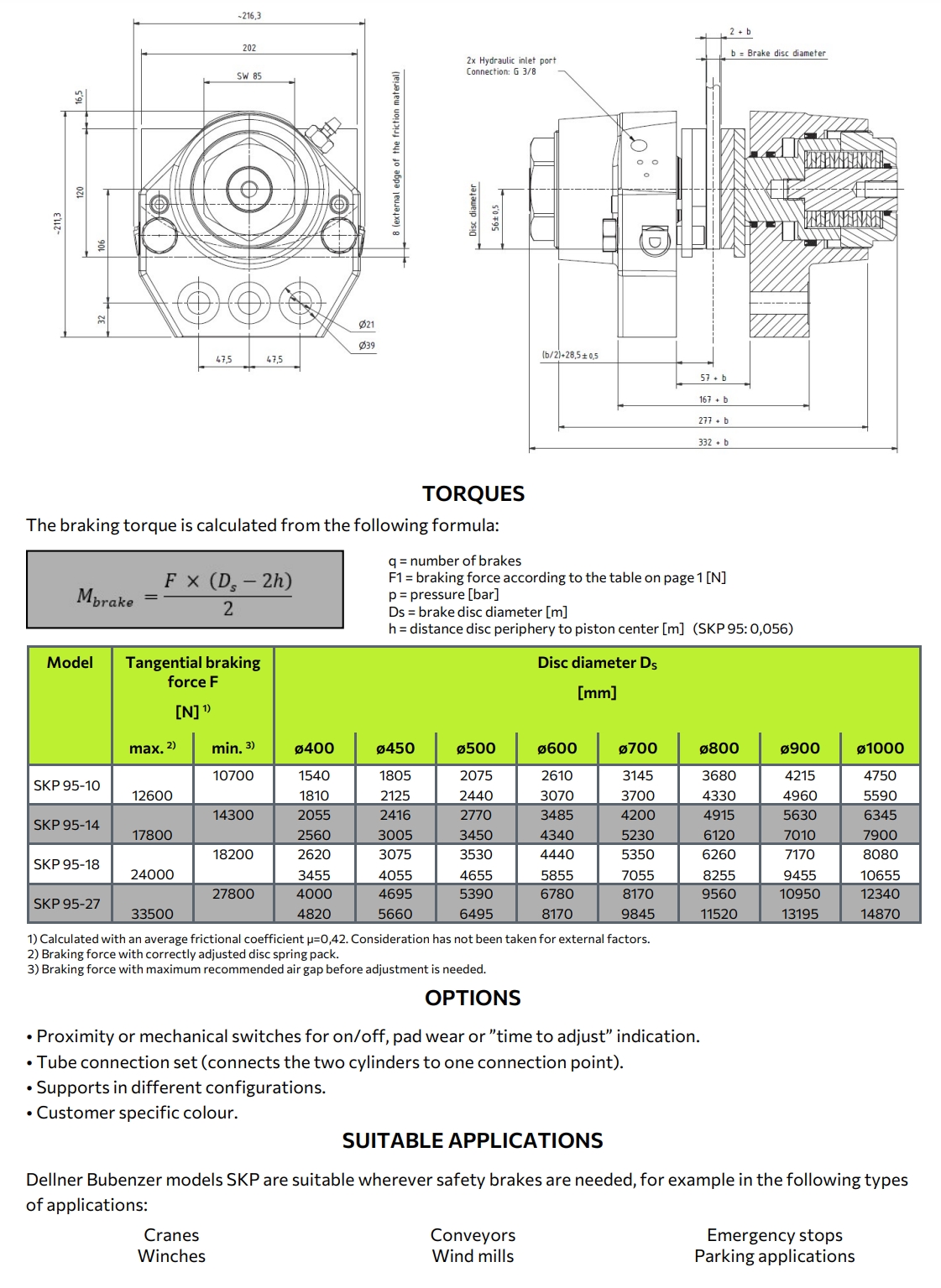

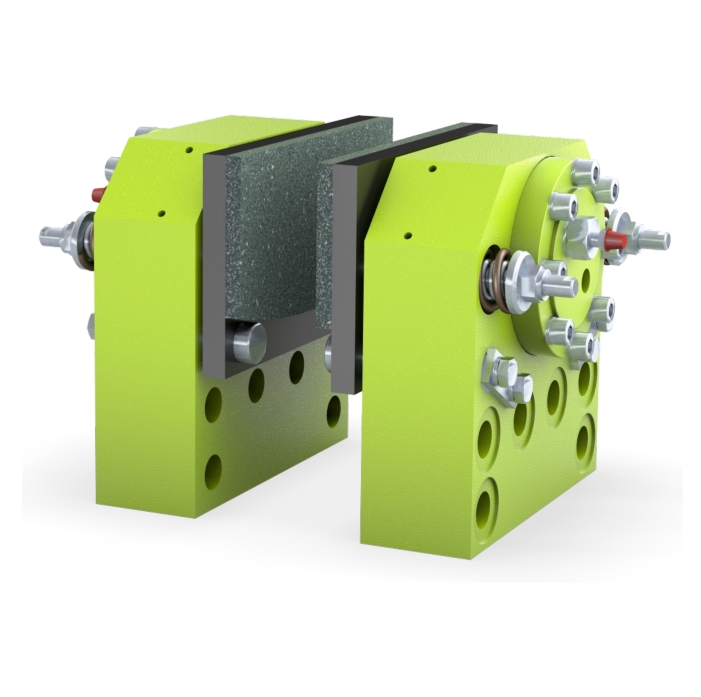

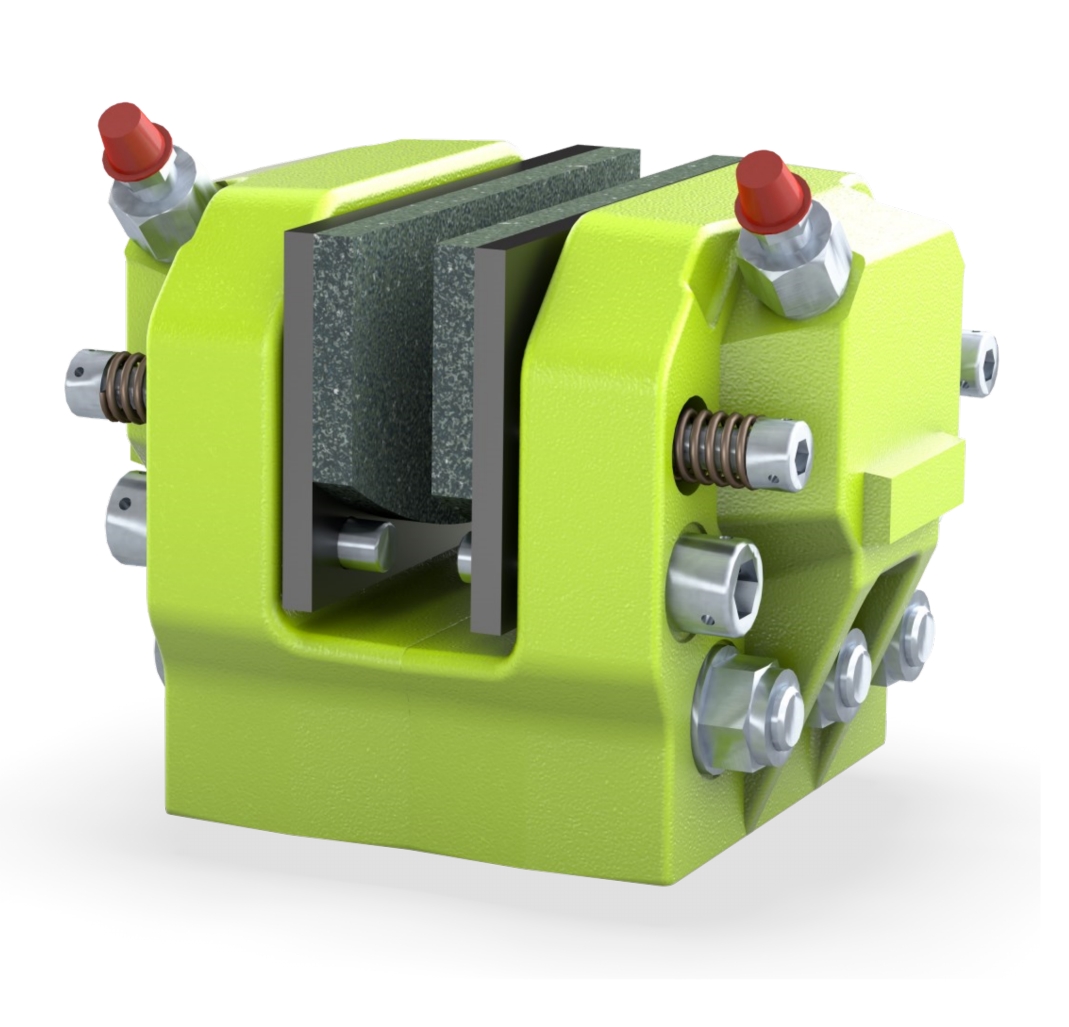

The SKP 95 Fail-Safe Brake is engineered for maximum reliability, delivering powerful braking force in safety-critical applications. Designed for easy maintenance and with a robust structure, it offers a long service life and requires minimal adjustments. The spring-applied mechanism ensures that the brake remains engaged even in the event of a power loss, making it a fail-safe option.

Key Features:

- Braking Force: Provides up to 33,500 N of braking force, ensuring optimal stopping power for heavy-duty applications.

- Spring-Applied, Hydraulic Release: Ensures safety by automatically engaging the brake when hydraulic pressure is lost, with hydraulic release for controlled braking.

- Dual or Single Housing Configuration: Available in dual or single housing configurations, with optional single-acting (SA) versions to suit specific operational needs.

- Easy Adjustment: Brake settings can be adjusted without the need for special tools, simplifying maintenance.

- Primary and Secondary Cylinder Seals: Features models with primary and secondary cylinder seals to prevent hydraulic leakage and ensure high reliability.

Optional Features:

- Electrical Indicators: Provides electrical monitoring for ON/OFF status, wear levels, and timing for brake adjustment, enhancing preventive maintenance and operational awareness.

- Support/Pedestal with Piping: The brake can be supplied with integrated piping, simplifying installation by providing a single connection point.

- Lining Material Alternatives: Various lining materials are available to meet specific application requirements and operational environments.

- Corrosion Protection: Includes options for corrosion-resistant surface treatments, including custom paint layers, stainless steel components, and special coatings for harsh or marine environments.

- Belleville Spring Configurations: Different Belleville spring setups are available to meet diverse braking force and operational demands.

Applications: The SKP 95 Fail-Safe Brake is suitable for industries that require reliable, fail-safe braking in both linear and rotary motion systems. Key applications include:

- Cranes and Hoisting Equipment: Critical for ensuring emergency stopping capability in lifting and moving heavy loads.

- Industrial Machinery: Ideal for controlling the motion of heavy-duty machines in manufacturing and processing plants.

- Marine and Offshore Applications: Well-suited for harsh environments, offering corrosion protection and reliable performance for marine operations.

- Wind Turbines and Energy Systems: Ensures safety in the operation of wind turbines by providing controlled braking in high-load conditions.

With the SKP 95 Fail-Safe Brake, industries benefit from a highly reliable, spring-applied braking system that ensures safe operations even in the most demanding environments.