Low Inertia Spring-Set Brake and clutch with Hydraulic/Pneumatic Release - Fail-Safe E-Stop Solution

Attribute | Details |

Model NO. | Low Inertia Clutch and Brake |

Installation | Vertical |

Usage | Paper Machinery, Packing Machinery, Ship, Stage Machinery, Machine Tool, Food Machinery, Chemical Machinery, Construction Machinery, Metallurgical Machinery |

Power Source | Pneumatic |

Torque Range | 340 to 1,204,000 Nm |

Actuation Method | Pneumatically Applied, Spring Released; Hydraulic |

Additional Features | Water Cooled, Copper Disc Clutches Available |

Industry Applications | Lumber Processing, Marine, Material Handling |

Equipment Compatibility | Metal Forming Equipment, Stamping Equipment, General Machinery |

Transport Package | Wooden Box |

Origin | China |

HS Code | 848360009 |

Product Description

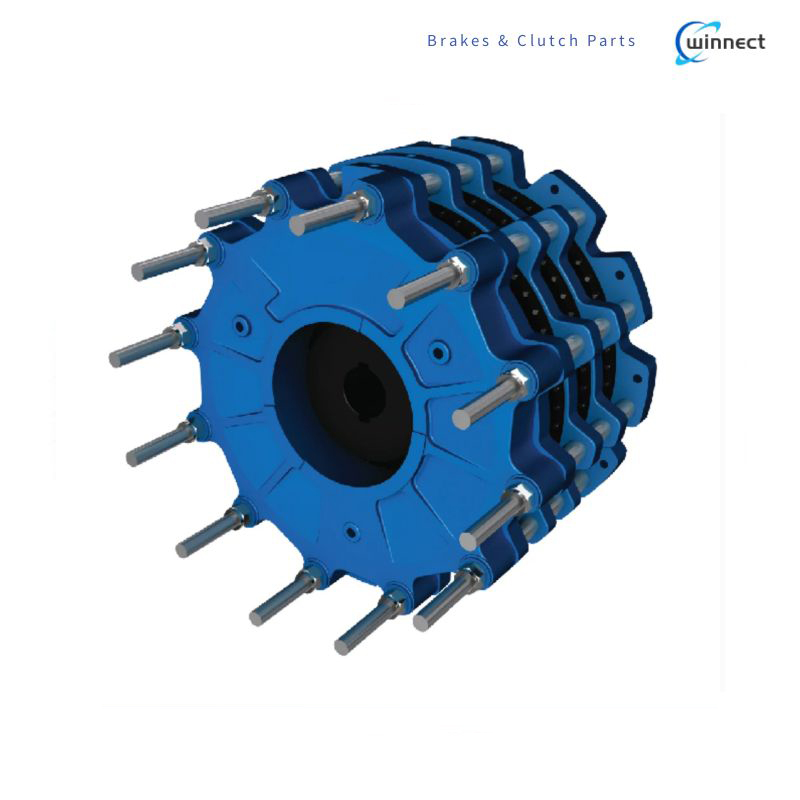

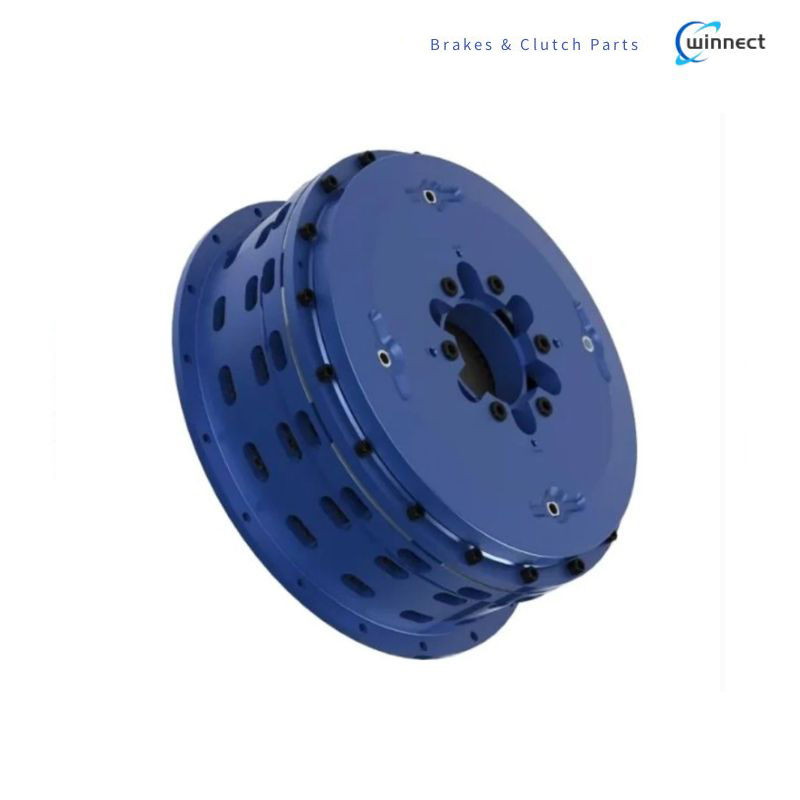

Our Low Inertia Clutches and Brakes are meticulously engineered to excel in high cycle applications and general clutch/brake duties. Designed for end-shaft mounting, typically on a flywheel, these units feature minimal part movement during start/stop operations. This significantly reduces acceleration time, allowing for more cycles per minute. The pneumatically applied and spring-released design ensures fast engagement and disengagement, enhancing operational efficiency.

Low Inertia Clutches and Brakes Overview:

- Application: Ideal for high cycle applications or general clutch/brake duties.

- Design: End-shaft mounting, typically on a flywheel.

- Actuation: Pneumatically applied, spring released; hydraulic actuation available.

- Engagement: Fast engagement and disengagement with air pressure design.

- Adjustment: Minimal adjustment required.

- Operation: Controlled slipping and high cycle operations.

- Cycle Life: High cycle life with predictable preventative maintenance.

- Plate Options: Slotted, solid, and ventilated center plates available.

- Bore Size: 22 - 480 mm.

- Lining Area: 250 - 94,000 cm².

- Max Slip Speed: 3,530 r/min.

Benefits

- Fast Cycle Times: Reduced acceleration times for more cycles per minute.

- High Efficiency: Smooth, controlled slipping for lower power demands and efficient heat dissipation.

- Long Service Life: High cycle life with minimal adjustment and predictable maintenance.

- Versatile Applications: Suitable for a wide range of industries and equipment types.

- Reliable Performance: Consistent torque development and fast, complete engagement and disengagement.

Our Low Inertia Clutches and Brakes are designed to meet the rigorous demands of various industrial applications, ensuring reliable performance, efficient operation, and long service life.

Product Features

Performance:

- Torque Range: 3,160 to 17,850,000 lb-in (340 to 1,204,000 Nm).

- Applications: Presses, shears, bulk material handling, and general industrial equipment.

- Features:

- Air applied, spring released disc style units.

- Torque proportional to air pressure applied.

- Designed to be free from effects of centrifugal force and self-energization.

- Low inertia start/stop parts reduce acceleration times and heat generation.

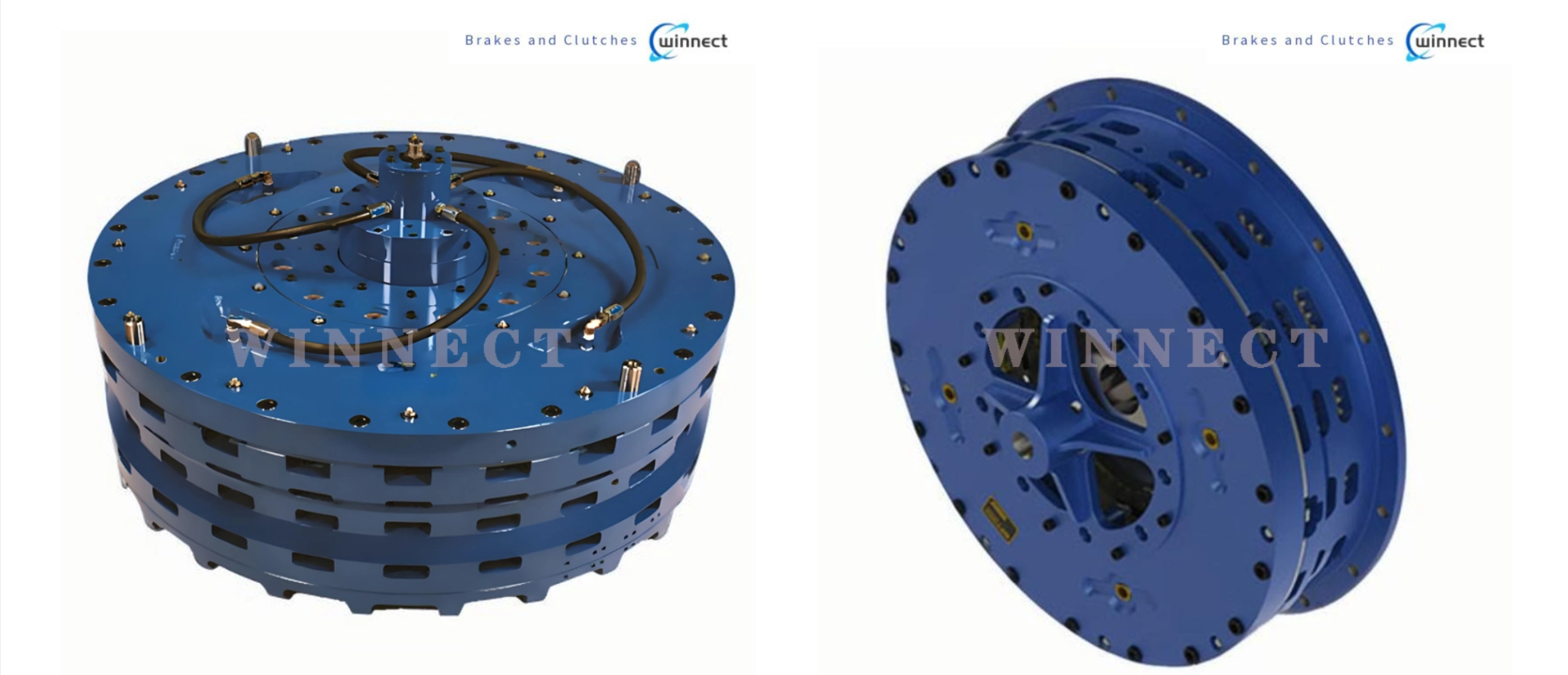

Air-Tube Disc Brakes:

- Design: Combines disc type clutch features with direct air engagement advantages.

- Engagement: Direct axial pressure application by compressed air in a full-circle tube.

- Operation: Smooth engagement without noise, shock, or impact, with complete release in a fraction of a second.

- Control: Clutches may be slipped moderately to control acceleration rate.

- Heat Dissipation: Heat generated by controlled slipping or high cycle rate operation is dissipated by centrifugal blower design.

Additional Features:

- Centrifugal Force Free: Designed to be completely free from effects of centrifugal force and self-energization.

- Torque: Developed in direct proportion to air pressure applied.

- Automation: Interfaces well with automated controls through simple air and/or electric circuits.

- Cooling: Water cooled, copper disc clutches available for high heat dissipation requirements.

- Compatibility: Operate perfectly when teamed with brakes in production situations requiring tension control, cyclic duty, or positioning.

Product Parameters

| Parameter | Specifications |

| Torque Range | 3,160 to 17,850,000 lb-in (340 to 1,204,000 Nm) |

| Bore Size | 22 - 480 mm |

| Lining Area | 250 - 94,000 cm² |

| Maximum Slip Speed | 3,530 rpm |

| Mounting Design | End-shaft mounting, typically on a flywheel |

| Actuation Method | Pneumatically applied, spring released; hydraulic actuation available |

| Cycle Life | High cycle life with predictable maintenance |

| Engagement | Fast engagement and disengagement with air pressure design |

| Plate Options | Slotted, solid, and ventilated center plates available |

| Features | - Air applied, spring released disc style |

| - Torque proportional to air pressure applied | |

| - Designed to be free from effects of centrifugal force | |

| - Low inertia start/stop parts | |

| Additional Features | - Centrifugal Force Free |

| - Water cooled, copper disc clutches available | |

| Applications | Presses, shears, bulk material handling, general industrial equipment |

| Industry Applications | Lumber processing, marine, material handling, metal production, paper manufacturing, etc. |

| Equipment Compatibility | Metal forming equipment, stamping equipment, general power transmission applications |

Industry Applications:

- Industries: Lumber processing, marine, material handling, metal production, metal forming, paper manufacturing, petroleum, rubber manufacturing, brick manufacturing, canning & bottling machines, air movement pumps, and agitators.

- Equipment: Metal forming equipment, stamping equipment, and general power transmission applications.

- Torque Range: From 2,340 lb-in (260 Nm) through 11,430,000 lb-in (1,301,800 Nm) static torque.

- Sizes: Low inertia and very low inertia clutches and brakes range from 4″ through 60″ diameter.