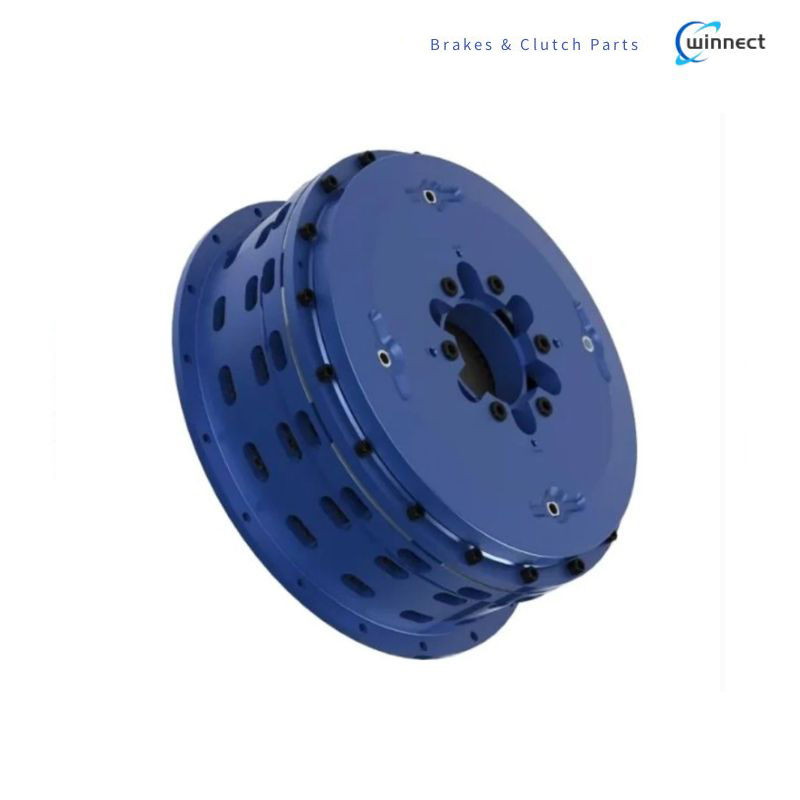

Heavy-Duty Water Cooled Brake with Hydraulic or Pneumatic Actuation

Attribute | Details | Attribute | Details |

Model NO. | WCB Brake | Installation | Vertical |

Usage | Paper Machinery, Packing Machinery, Ship, Stage Machinery, Machine Tool, Food Machinery, Chemical Machinery, Construction Machinery, Metallurgical Machinery | Power Source | Hydraulic |

Brake Type | Disc Brake, Water Cooled Brake | Cooling Method | Water Cooling, External Cooling |

Actuation Method | Hydraulic Actuation, Pneumatic Actuation | Industry Application | Mining, Marine, Construction |

Equipment Type | Heavy Machinery, Drawworks, Mooring Winch | Transport Package | Wooden Box |

Origin | China | HS Code | 8483600090 |

Product Description

Product Details for Water Cooled Brake (WCB)

Models

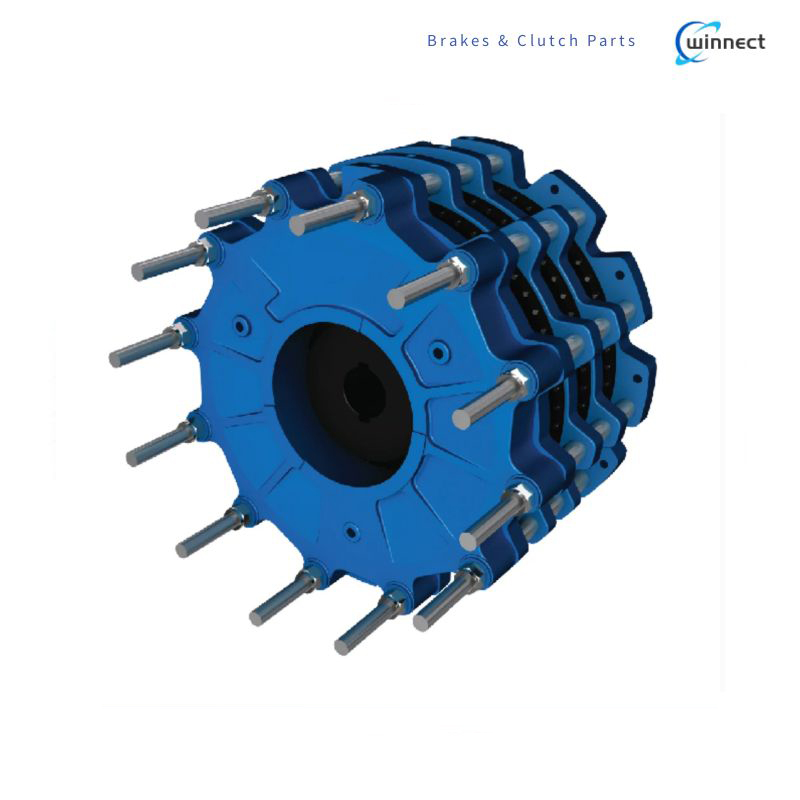

WCB Series: WCB2, WCBD, and WCB3 models with external cooling disc brakes.

- WCS Series: Externally cooled, spring-applied brakes.

- WCSB Series: Combines water-cooled and air-cooled disc brakes in one unit.

- Models: 108WCB, 208WCB, 308WCB, 114WCB, 214WCB, 314WCB, 118WCB, 218WCB, 318WCB, 418WCB, 124WCB, 224WCB, 324WCB, 424WCB, 136WCB, 236WCB, 336WCB, 436WCB, 148WCB, 248WCB, 348WCB, 448WCB.

Product Range

WCB2/WCBD/WCB3 Series:

- High Coefficient Linings: Special high-coefficient linings provide increased torque.

- Dual Piston Design: Optional dual piston design enhances control capabilities.

- Cooling Systems: Suitable for both open and closed-loop coolant systems.

- Thermal Capacity: Up to 5,200 HP (3,878 kW).

- Torque Capacity: Up to 1,180,000 lb-in (133,322 Nm).

WCSB Series:

- Integrated Design: Combines water-cooled and air-cooled brakes in one package, providing dynamic tensioning, static holding, and emergency stop functions, eliminating the need for multiple brakes.

- Friction Material: Specially formulated friction material combined with copper alloy surfaces to reduce or eliminate stick-slip characteristics.

- Thermal Capacity: Up to 3,900 HP (2,908 kW).

- Torque Capacity: Up to 5,548,000 lb-in (626,369 Nm).

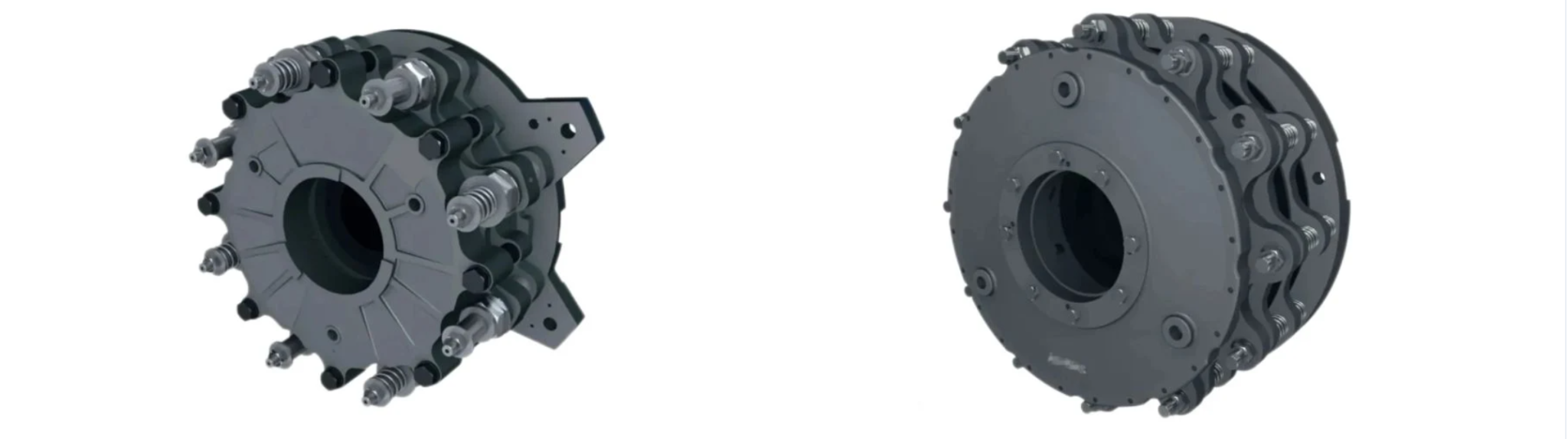

WCS Series:

- Emergency Stop Applications: Spring-applied brakes suitable for emergency stop applications.

- Dynamic/Static Torque Ratio: 1:1 dynamic to static torque ratio.

- Thermal Capacity: Up to 2,600 HP (1,939 kW).

- Torque Capacity: Up to 1,030,000 lb-in (116,287 Nm).

Product Features

- Actuation Options: Hydraulic or pneumatic actuation.

- Clutch Configurations: Various clutch configurations.

- Spring-Applied Brake: Spring-applied with hydraulic or pneumatic release.

- Dual Actuation: Dual hydraulic or pneumatic actuation options.

- Marine Corrosion Protection: Full marine corrosion protection package.

- Certifications: Type approval certifications in DNV and ABS.

Product Application

- Drawworks

- Mooring winches

- Dynamometers

- Paper mills

- Tension brakes

- Unwind stands

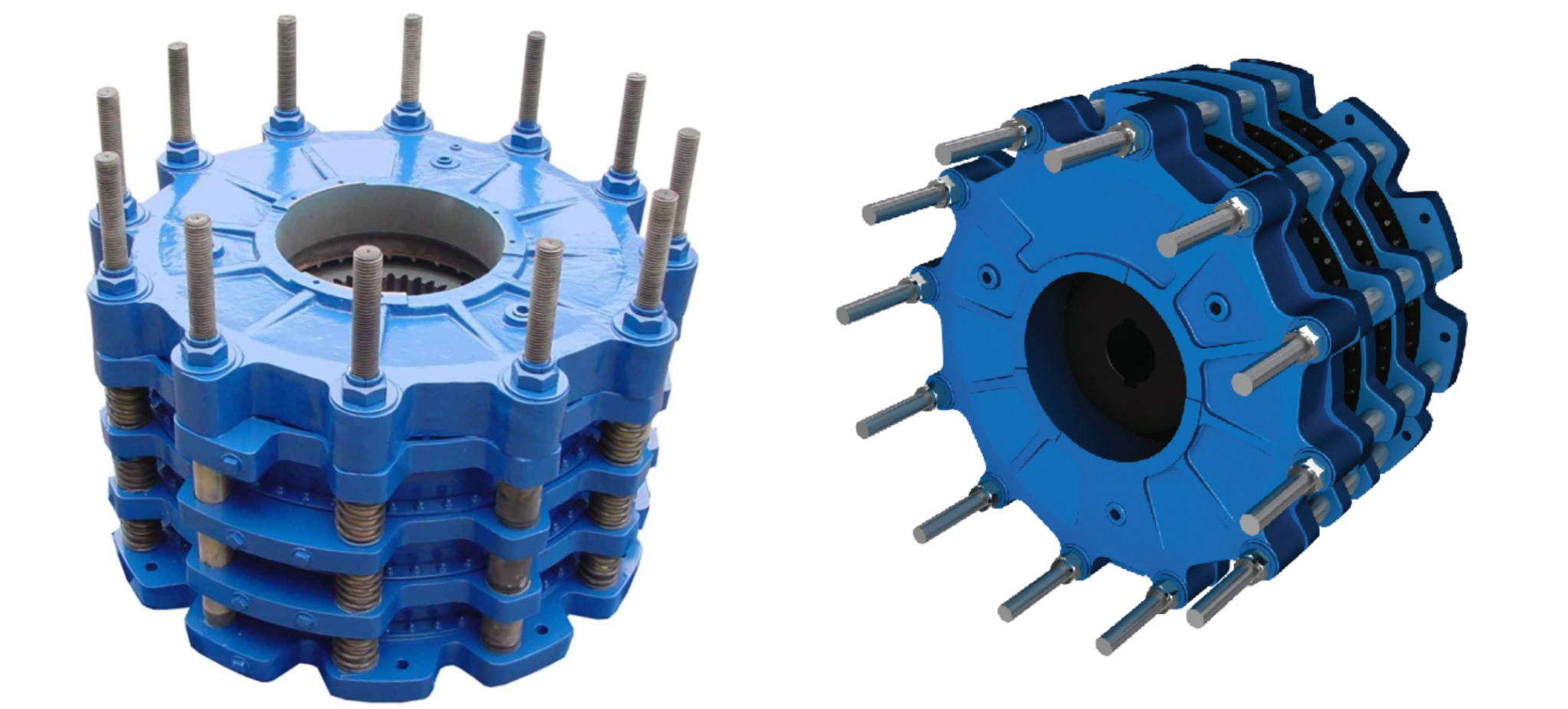

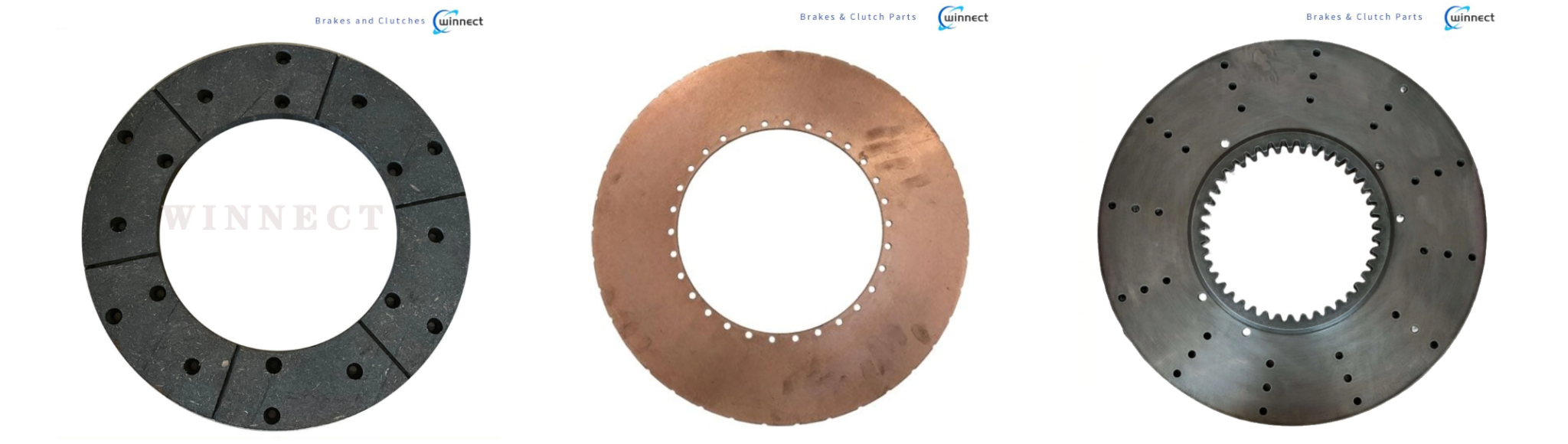

Components

- Support ring segment OD

- Support ring segment ID

- Backplate water jacket

- Copper wear plate

- Drive plate

- Hub

- Nut and bolt

- Friction disc

- Flat head screw

- Release spring

- Center water jacket

- Floating water jacket

- Locking nut

- Stud

- Flat washer

- Airtube holding plate

- Pressure plate

- Airtube

- Clamp tube

- Wear spacer

Product Parameters

| Description | Part Number | Clutch Size | Description | Part Number | Clutch Size |

| Mounting Flange Assembly | R24-04-304 | 24WCB2 | Mounting Flange Assembly | R36-04-307 | 36WCB2 |

| Mounting Flange | R24-04-305 | 24WCB2 | Mounting Flange | R36-04-301 | 36WCB2 |

| Wear Plate | R24-11-307 | 24WCB2 | Wear Plate | R36-11-301 | 36WCB2 |

| Bolt | X20-08-054 | 24WCB2 | Bolt | X20-08-123 | 36WCB2 |

| Nut | X20-20-004 | 24WCB2 | Nut | X20-20-016 | 36WCB2 |

| Screw | X20-01-002 | 124WCB2 | Screw | X20-01-011 | 136WCB2 |

| Brake Disc Assembly | R24-08-304 | 24WCB2 | Brake Disc Assembly | R36-08-303 | 36WCB2 |

| Brake Friction Disc | W24-07-301 302 | 24WCB2 | Brake Friction Disc | W36-07-301 302 | 36WCB2 |

| Brake Disc Core | R24-08-303 | 24WCB2 | Brake Disc Core | R36-08-302 | 36WCB2 |

| Clamp | R24-09-302 | 124WCB2 | Clamp | R36-09-301 | 136WCB2 |

| Clamp | R24-09-301 | 224WCB2 | Clamp | R36-09-300 | 236WCB2 |

| Clamp | R24-09-303 | 324WCB2 | Clamp | R36-09-302 | 336WCB2 |

| Clamp | R24-09-307 | 424WCB2 | Clamp | R36-09-303 | 436WCB2 |

| Floating Water Jacket Assembly | R24-11-309 | 24WCB2 | Floating Water Jacket Assembly | R36-11-314 | 36WCB2 |

| Floating Water Jacket | R24-11-306 | 24WCB2 | Floating Water Jacket | W36-11-302 | 36WCB2 |

| Flat Washer | X20-27-001 | 24WCB2 | Flat Washer | X20-27-010 | 36WCB2 |

| Nut | X20-20-030 | 24WCB2 | Nut | X20-20-043 | 36WCB2 |

| Airbag Fixing Disc | R24-02-304 | 24WCB2 | Airbag Fixing Disc | R36-02-301 | 36WCB2 |

| Gasbag | R25-20-900 | 24WCB2 | Gasbag | R36-20-901 | 36WCB2 |

| Plate | R24-03-305 | 24WCB2 | Plate | W36-03-301 | 36WCB2 |

| Gear | W24-01-306 | 124WCB2 | Gear | R36-01-303 | 36WCB2 |

| Gear | R24-01-305 | 224WCB2 | Gear | R36-01-302 | 36WCB2 |

| Gear | R24-01-304 | 324WCB2 | Gear | R36-01-304 | 36WCB2 |

| Gear | R24-01-307 | 424WCB2 | Gear | R36-01-307 | 36WCB2 |

| Wear Ring | R24-33-300 | 24WCB2 | Wear Ring | R36-33-300 | 36WCB2 |

| Static Disk Core Assembly | W24-11-308 | 24WCB2 | Static Disk Core Assembly | W36-11-313 | 36WCB2 |

What are Water-Cooled Brake Systems?

A water-cooled brake disc consists of a central and stationary aluminum cooling plate with an internal chamber that circulates water coolant. Cast iron sectors mounted on opposite sides of the disc plate allow contact from the friction material carried by discs on the shaft to be slowed down. The cooling plate and iron cast sectors are separated by thermally insulative layers such as thin air gaps. The sectors retain the heat generated from braking for a short period, which is then transferred to the water over a longer period at a rate determined by the conductance of the thermally insulative layers. This design efficiently absorbs and dissipates braking heat, mitigating the risk of overheating.

When are Water-Cooled Brakes Necessary?

Traditional air-cooled braking systems may not suffice in heavy machinery due to insufficient airflow for cooling. In such cases, water-cooled brakes provide a more effective cooling solution. Water has a higher density and faster heat transfer rate compared to air, making it suitable for applications where space is limited and optimal cooling is required.