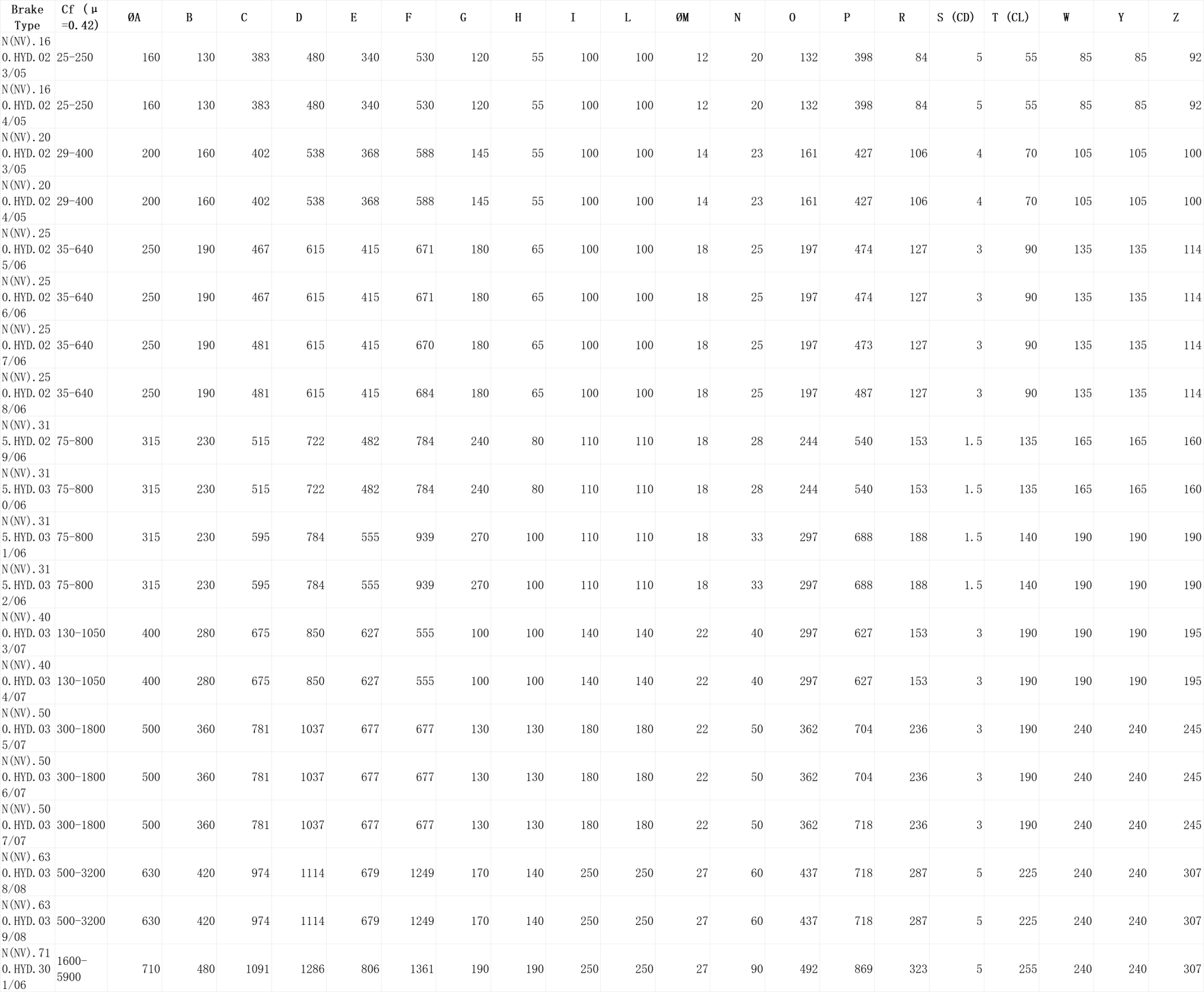

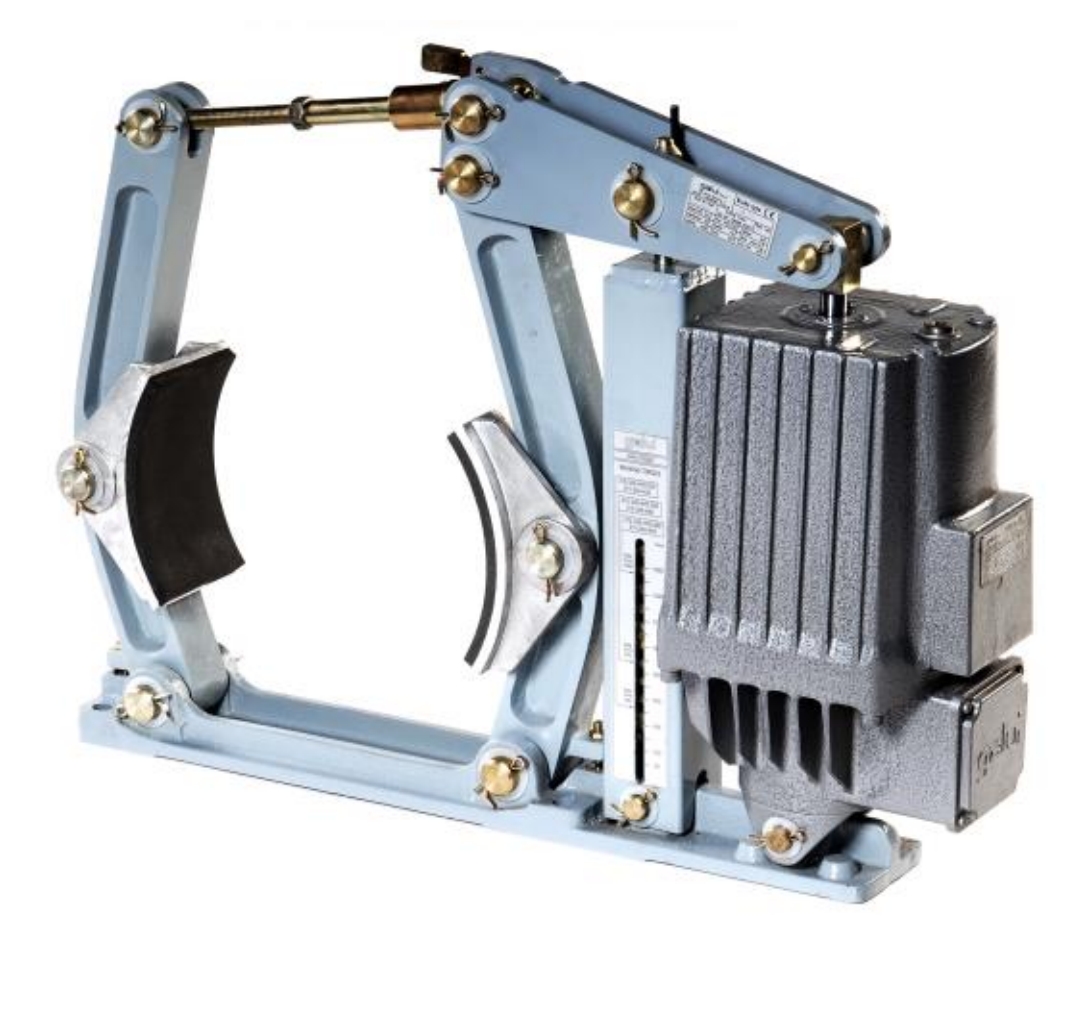

GALVI DIN Failsafe Shoe Brakes with Electrohydraulic Thrusters

DIN 15435 Standard Shoe Brakes with Adjustable Spring Set and HYDRO GALVI Electrohydraulic Thrusters

The GALVI DIN Failsafe Shoe Brakes are designed in accordance with DIN 15435 standards and feature electrohydraulic HYDRO GALVI Thrusters. These brakes ensure reliable, failsafe braking performance for various industrial applications, offering customizable options and robust construction for long-term use.

Product Details:

The GALVI DIN Failsafe Shoe Brakes provide exceptional braking force using electrohydraulic thrusters that ensure immediate response and consistent braking. Designed with high-quality materials and advanced features, these brakes offer durability, reliability, and easy maintenance, making them ideal for a wide range of heavy-duty applications.

Key Features:

- HYDRO GALVI Electrohydraulic Thruster: Equipped with an IP65 rated, class F electrohydraulic thruster (HYD) to ensure efficient, consistent performance.

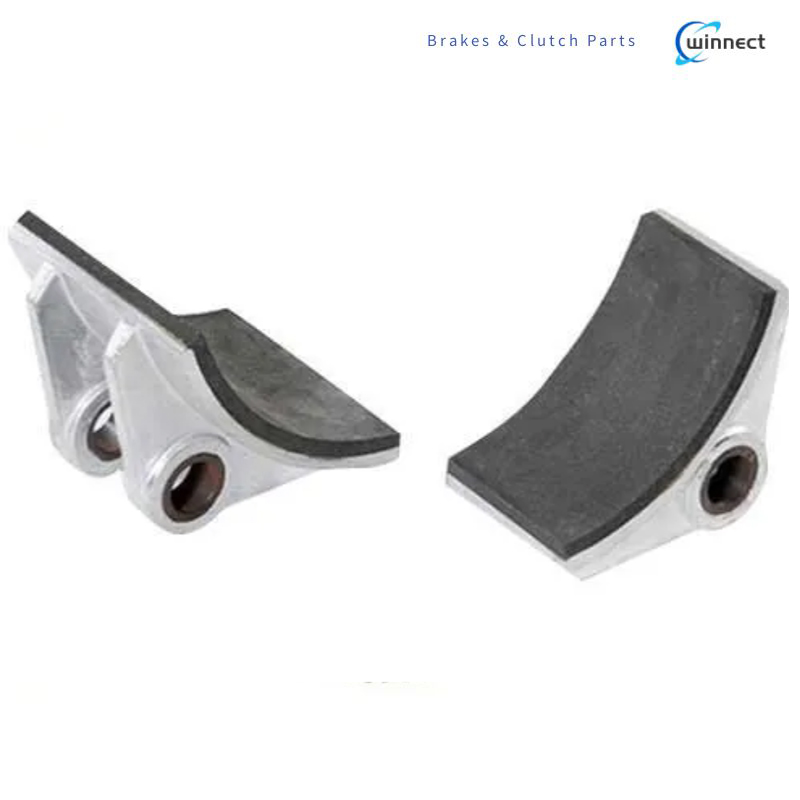

- Aluminum Brake Shoes: Manufactured according to DIN 15435 standards, the brake shoes are made of aluminum with steel bushings for enhanced strength (CD).

- Asbestos-Free Linings: Featuring a friction coefficient of μ = 0.42, the brake linings provide excellent braking performance without the use of asbestos (42).

- Galvanized Components: The pins, tie rods, and small items are galvanized for corrosion resistance and long-term protection (PS, ZN).

- Self-Lubricating Bushes: Installed on the main pins to reduce friction and ensure smooth operation without the need for frequent lubrication (AU).

- Epoxy Antisalt Paint: The final coating is epoxy antisalt paint in grey RAL 7001, offering additional protection against harsh environments.

- Material Construction:

- Cast iron levers and base for models with diameters between 160 mm to 500 mm.

- Steel levers and base for models with diameters of 630 mm and 710 mm, ensuring full contact with the floor for stability.

Optional Features:

- Self-Adjusting Device (NV): Automatically adjusts the brake shoes for optimal braking performance.

- Extra-Wide Brake Shoes (CL): Brake shoes 1.5 times wider than the standard DIN shoes for enhanced braking force.

- Stainless Steel Pins (SS): Provides additional corrosion resistance in challenging environments.

- Lubricators on Main Pins (GR): Optional lubricators for easy maintenance of the main pins.

- Open Position Mechanical Microswitch (FIA-L/R): Available on either the left (L) or right (R) side for monitoring brake status.

- Linings Wear Microswitch (FIC-L/R): Allows monitoring of brake lining wear from either the left (L) or right (R) side.

- Manual Opening and Locking System (HAN-L/R): Manual operation available on the opposite side to the FIA microswitch.

- Supporting Spheres (ORZ-L/R): For vertical brake axis applications (not available for models with smaller thrusters such as 024, 031, 051, 081). Requires a thruster with a foot rotated 90 degrees.

- Hydraulic Thruster Valves:

- Lowering Valve (LO): Not available for thrusters 024, 031, 051, and 081.

- Lifting Valve (LI): Not available for thrusters 024, 031, 051, and 081.

Applications: The GALVI DIN Failsafe Shoe Brakes are suited for heavy-duty applications requiring failsafe braking solutions, such as:

- Cranes and Hoisting Systems: Ensures safe braking in industrial and construction equipment.

- Marine and Offshore Equipment: Durable design with corrosion-resistant options, ideal for marine environments.

- Steel Mills and Heavy Machinery: Reliable braking for high-torque equipment.

- Wind Turbines and Energy Systems: Provides safe, controlled stopping in energy systems.

With a range of options and features tailored to meet specific application needs, the GALVI DIN Failsafe Shoe Brakes deliver top-notch performance in any industrial setting.

Winnect (Shanghai) International Industrial & Trade Co., Ltd.

86 400-991-4319

sales@winnect.cn