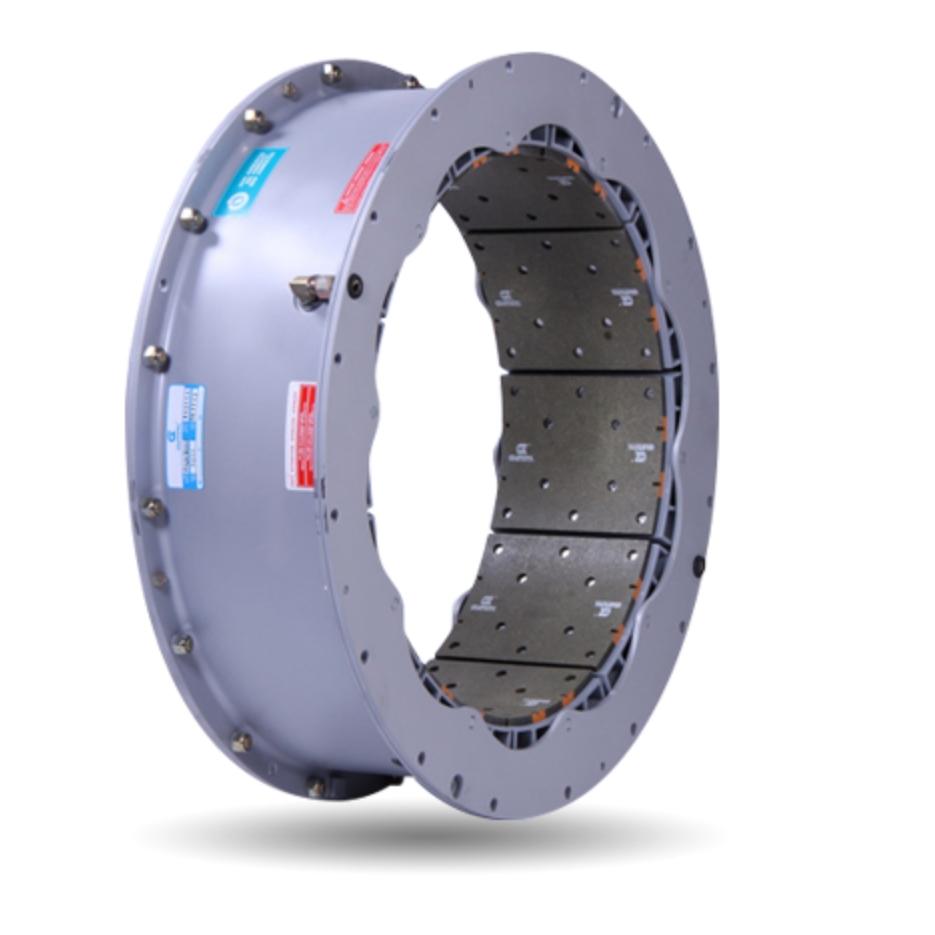

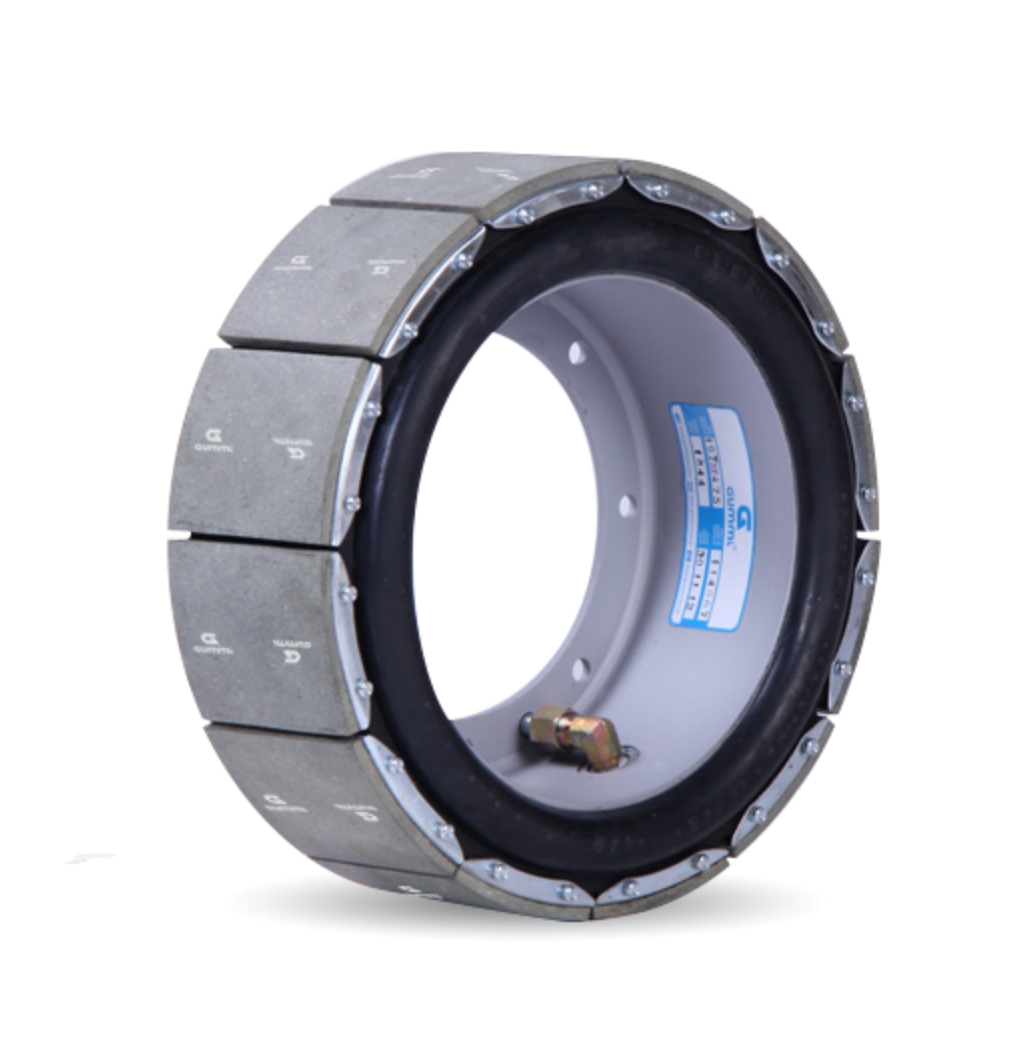

GUMMI A-Series Elastic Tire Couplings

Product Details:

Misalignment and Vibration Absorption

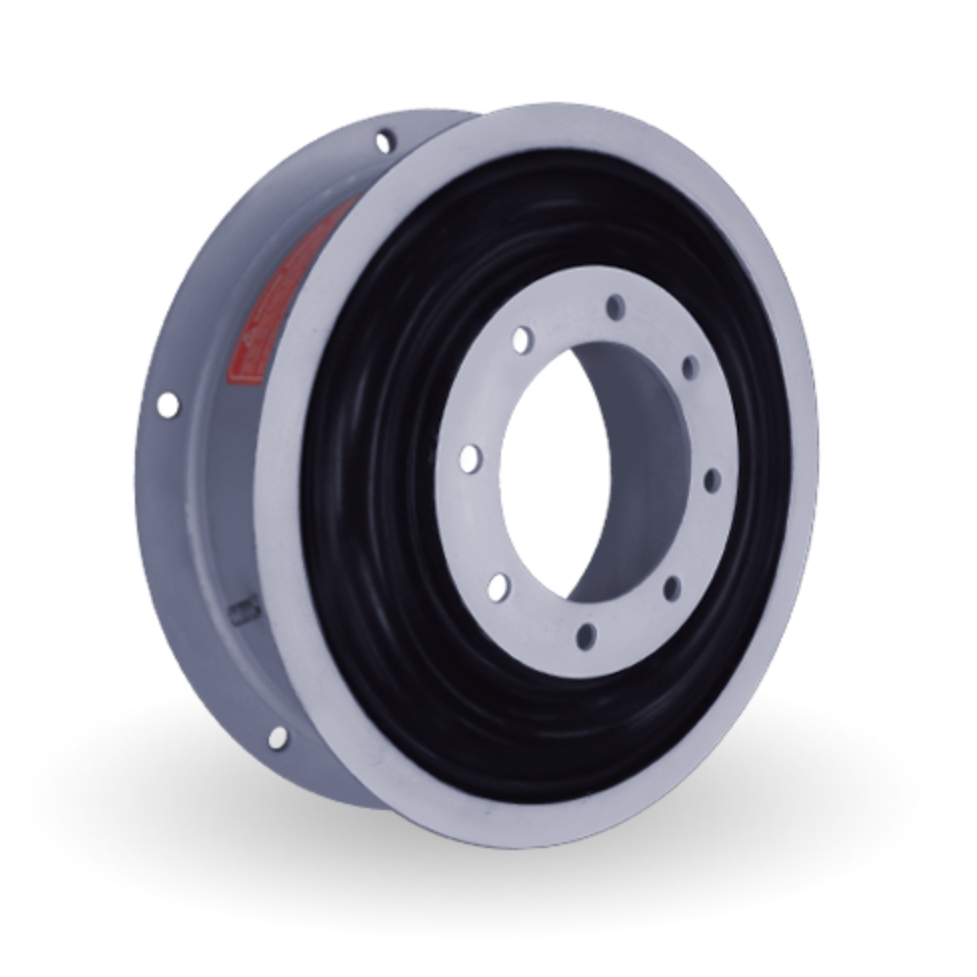

GUMMI A-Series couplings compensate for shaft misalignment, reducing the risk of bearing and seal failures. With an elastic center, these couplings minimize transmitted vibrations by about 70%, ensuring a longer lifespan for transmission components.High Torque Capacity

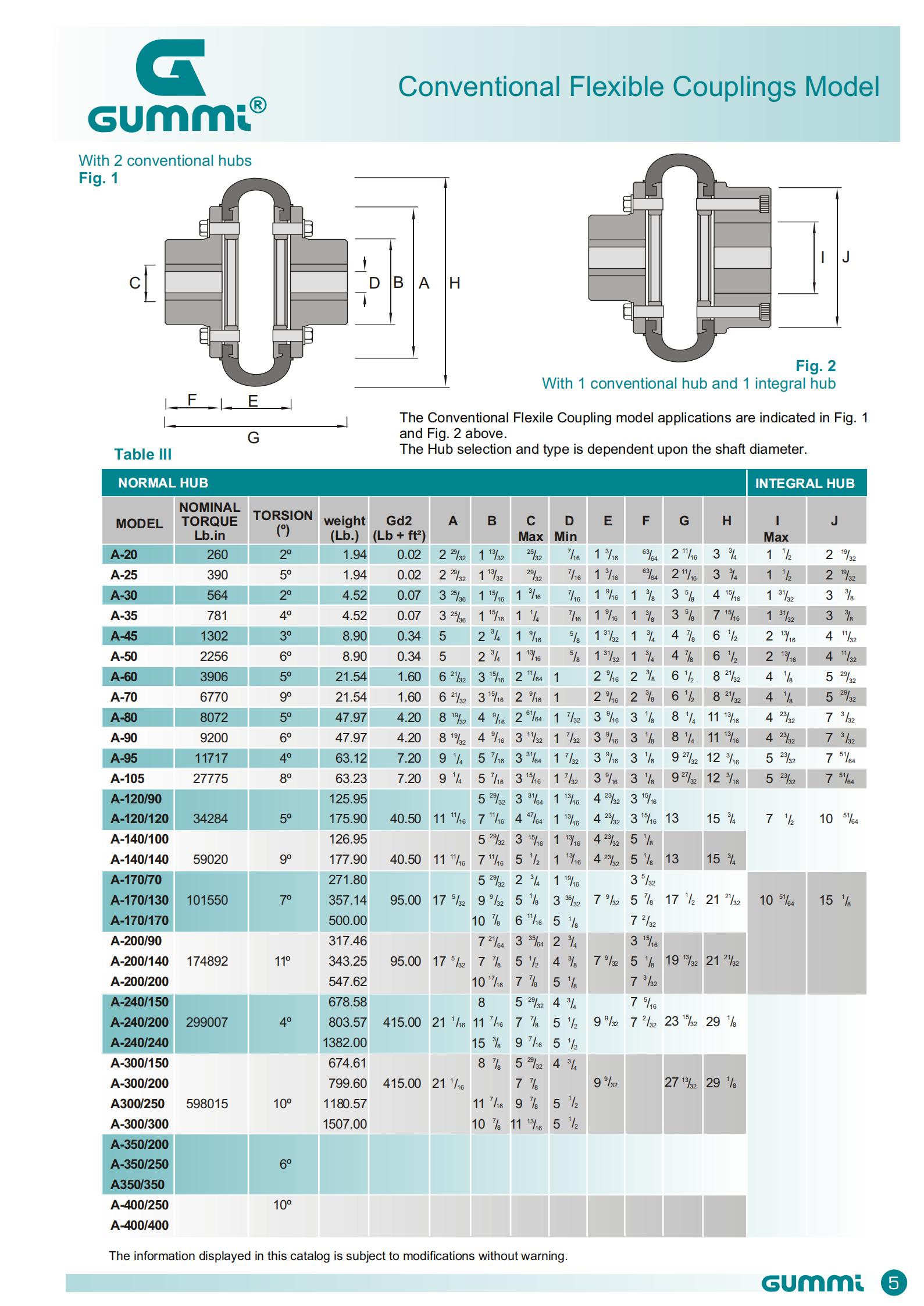

With torque ranges from 38 Nm to 168,750 Nm, the GUMMI couplings handle demanding industrial applications, ensuring reliable power transmission and reducing downtime due to mechanical failure.Multiple Configurations

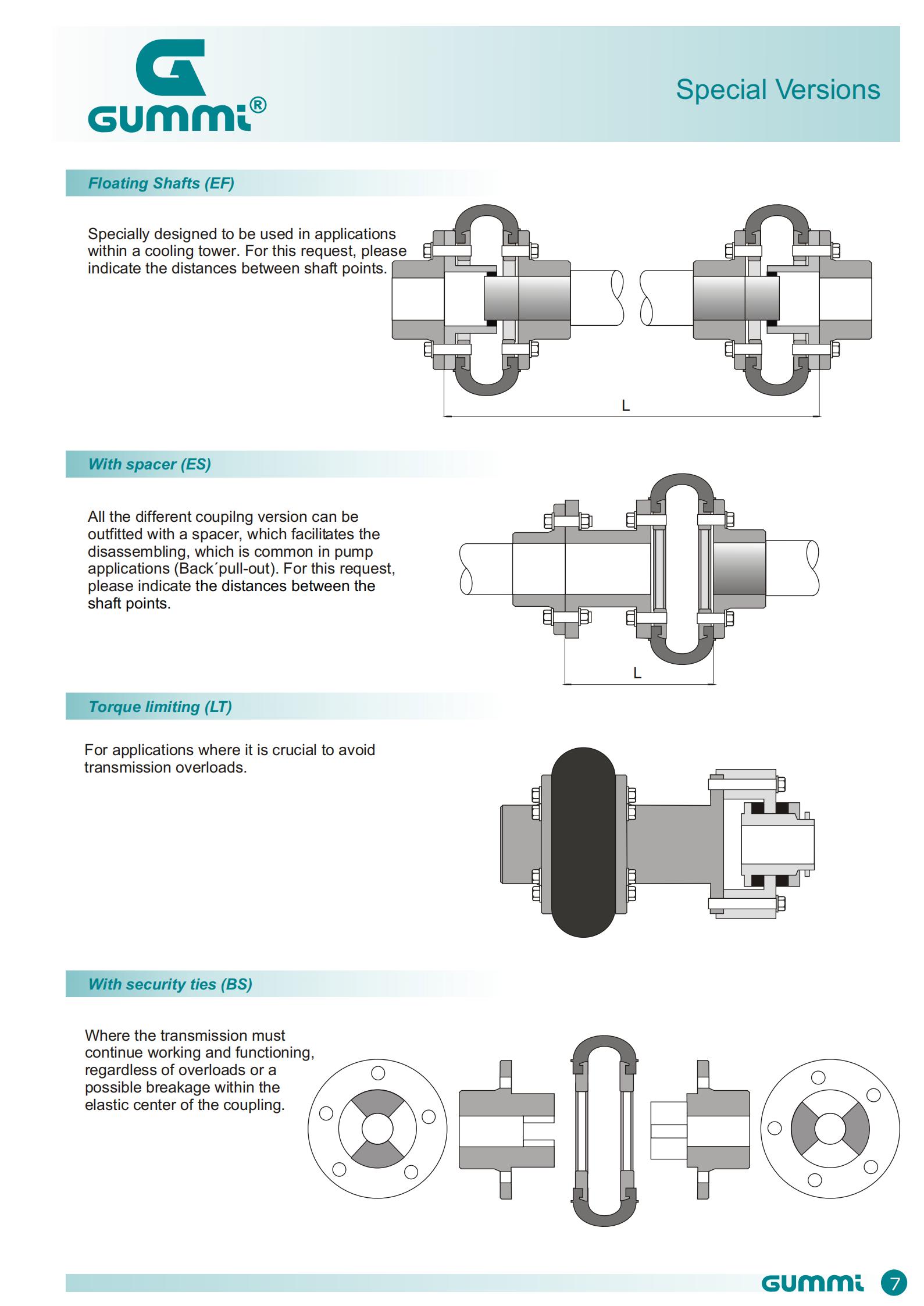

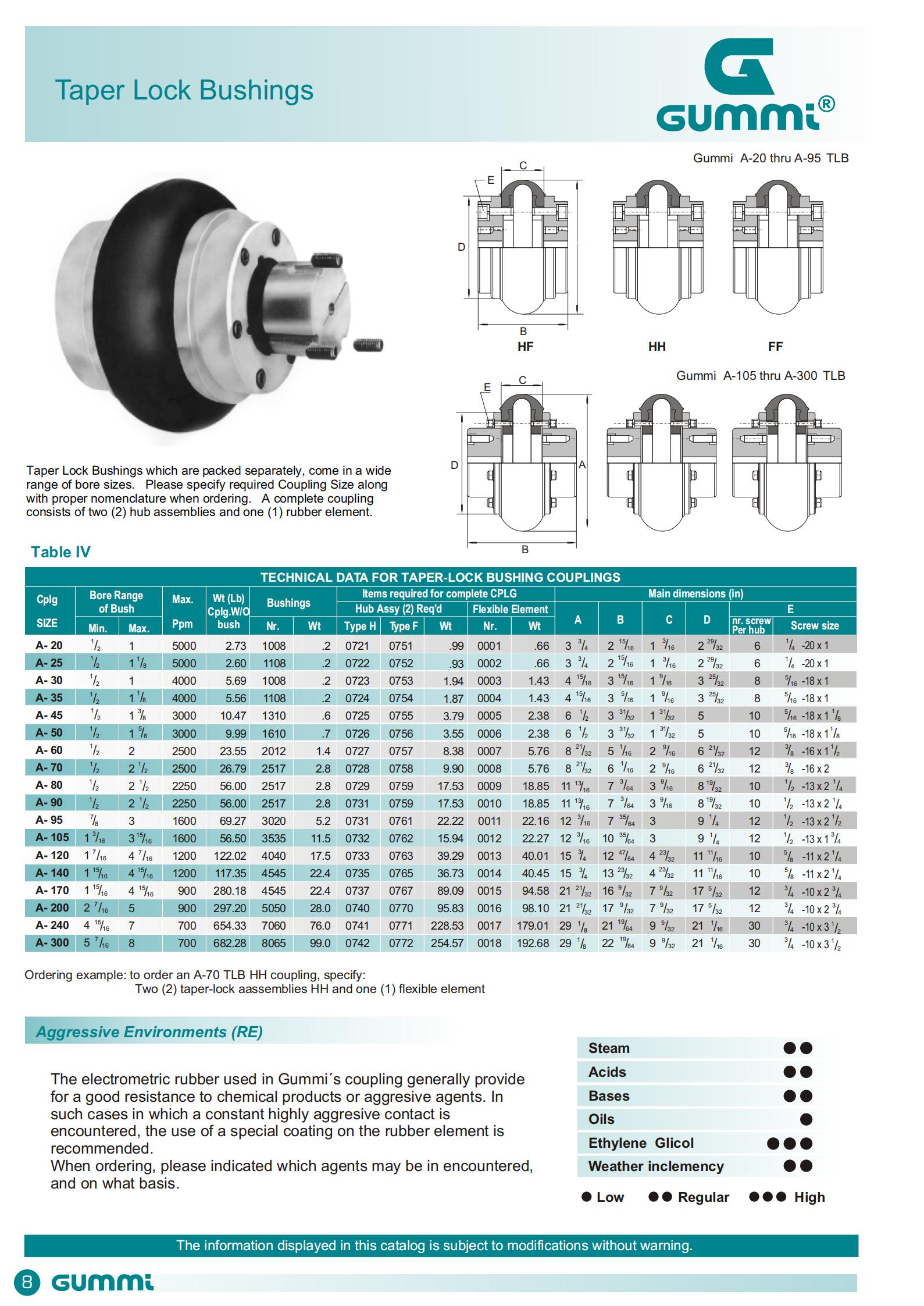

Available in a wide variety of sizes from A-20 to A-400, the GUMMI A-Series couplings also come with optional synthetic coating for use in aggressive environments (RE). The couplings offer various hub designs such as standard hubs (CN), integral hubs (CI), axial hubs (CX), and flanged hubs (CF). Special configurations are available with brake discs (DF) and brake pulleys (APF), providing flexibility for different applications.Durable and Maintenance-Free Design

The construction of these couplings ensures symmetry, balance, and safety, as the elastic center is free of cuts or weak points. No lubrication is required, reducing maintenance efforts and extending the service life.Applications:

Thanks to their versatility, GUMMI A-Series couplings are widely used in industries like steel, paper production, food processing, petroleum, mining, and marine sectors. They are especially beneficial in systems with diesel engines, axial displacement, and large-diameter shafts.Easy Installation and Replacement

The coupling consists of a single elastic element, which makes installation and replacement quick and easy. There is no need to move other parts during replacement, minimizing machine downtime.Quality Assurance

All GUMMI products are manufactured in accordance with ISO 9001 quality standards. With over 45 years of industry experience, GUMMI guarantees the highest quality materials and technical support to ensure superior performance.No Lubrication Required

The couplings are constructed from materials that eliminate the need for lubrication, which further simplifies maintenance and reduces operational costs.Economy and Efficiency

The long service life of the elastic center helps to extend intervals between replacements, reducing downtime and saving on spare parts, lubricants, and inventory costs.