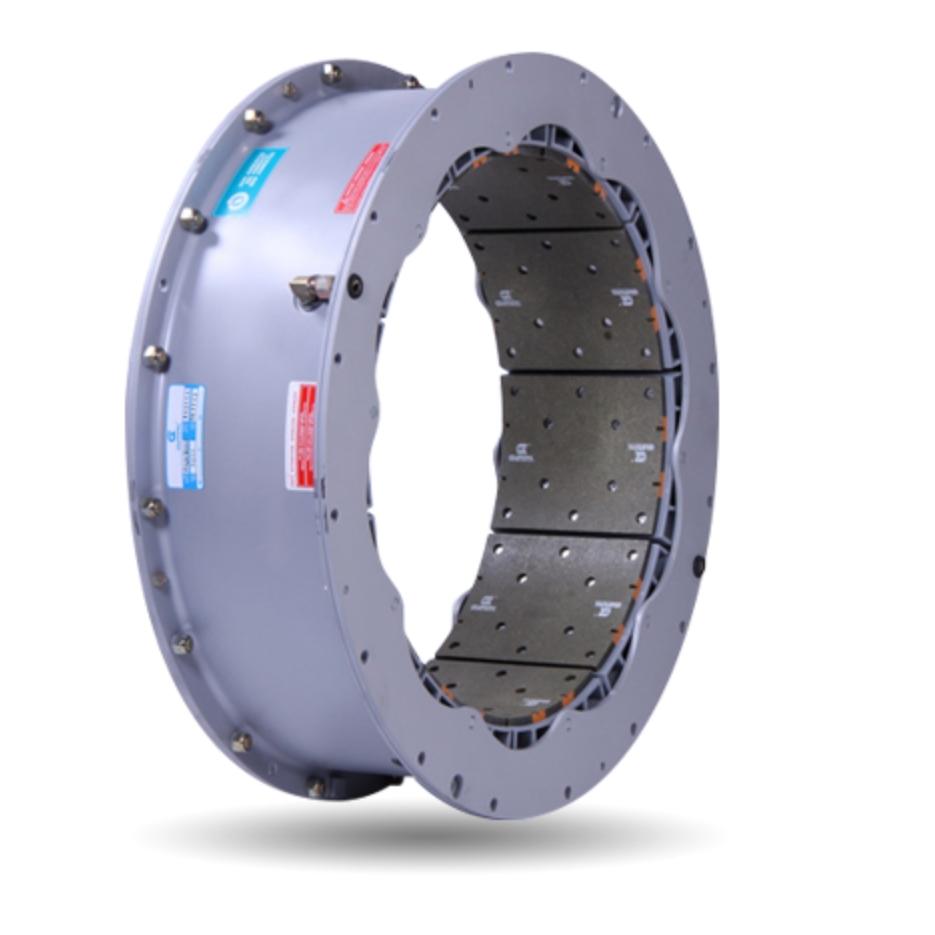

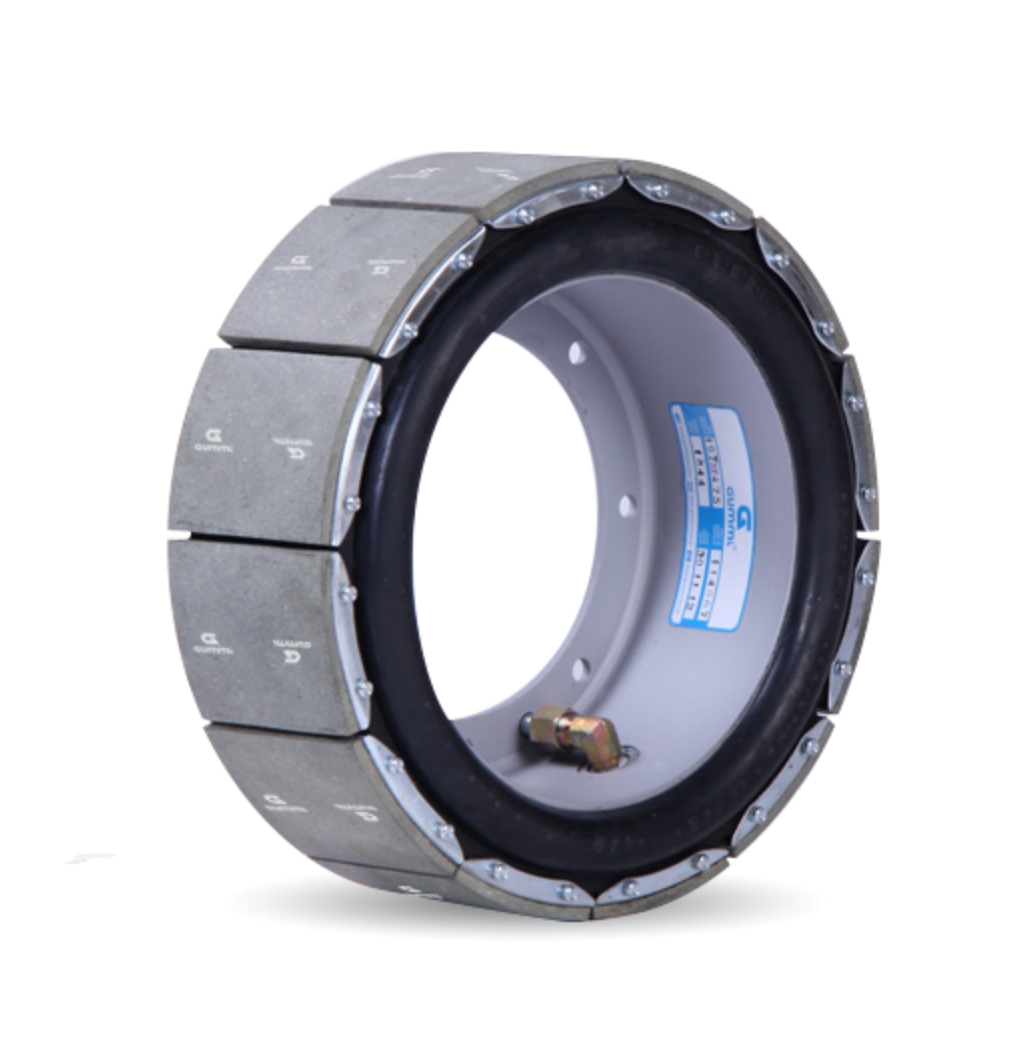

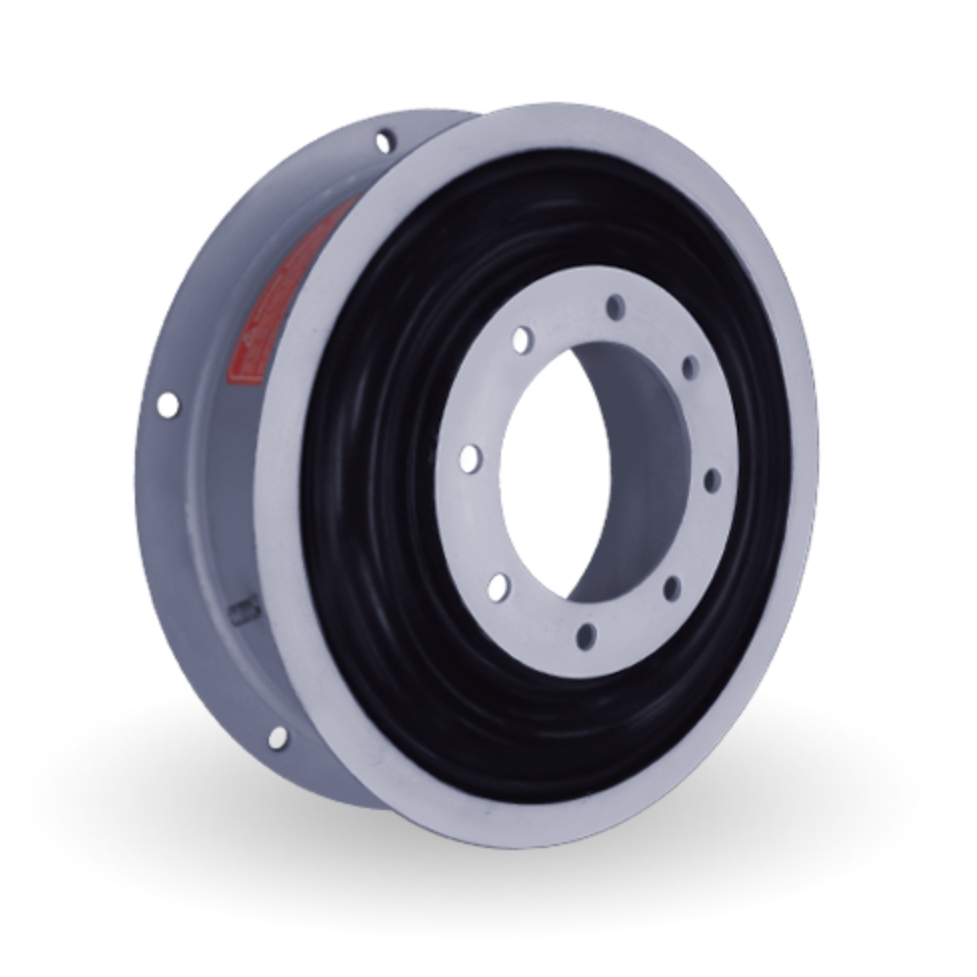

GUMMI AN-Series Pneumatic Rubber Coupling

Product Details:

High Torque Fluctuation Protection

GUMMI AN pneumatic couplings excel at controlling high torsional fluctuations. Their flexible rubber chambers absorb misalignments and reduce transmitted vibrations and shocks, preventing damage to key transmission components.Adjustable Flexibility

One of the most significant advantages of GUMMI AN couplings is the adjustable flexibility, which can be tuned by modifying the air pressure inside the pneumatic chamber. This allows for precise control over torsional deflection, making the coupling adaptable to various load conditions.Noise Reduction & Electrical Insulation

The couplings provide exceptional noise reduction by minimizing the transmission of vibrations from one machine to another, making operations quieter. Additionally, they serve as excellent electrical insulators, further protecting equipment.Versatile Installation Options

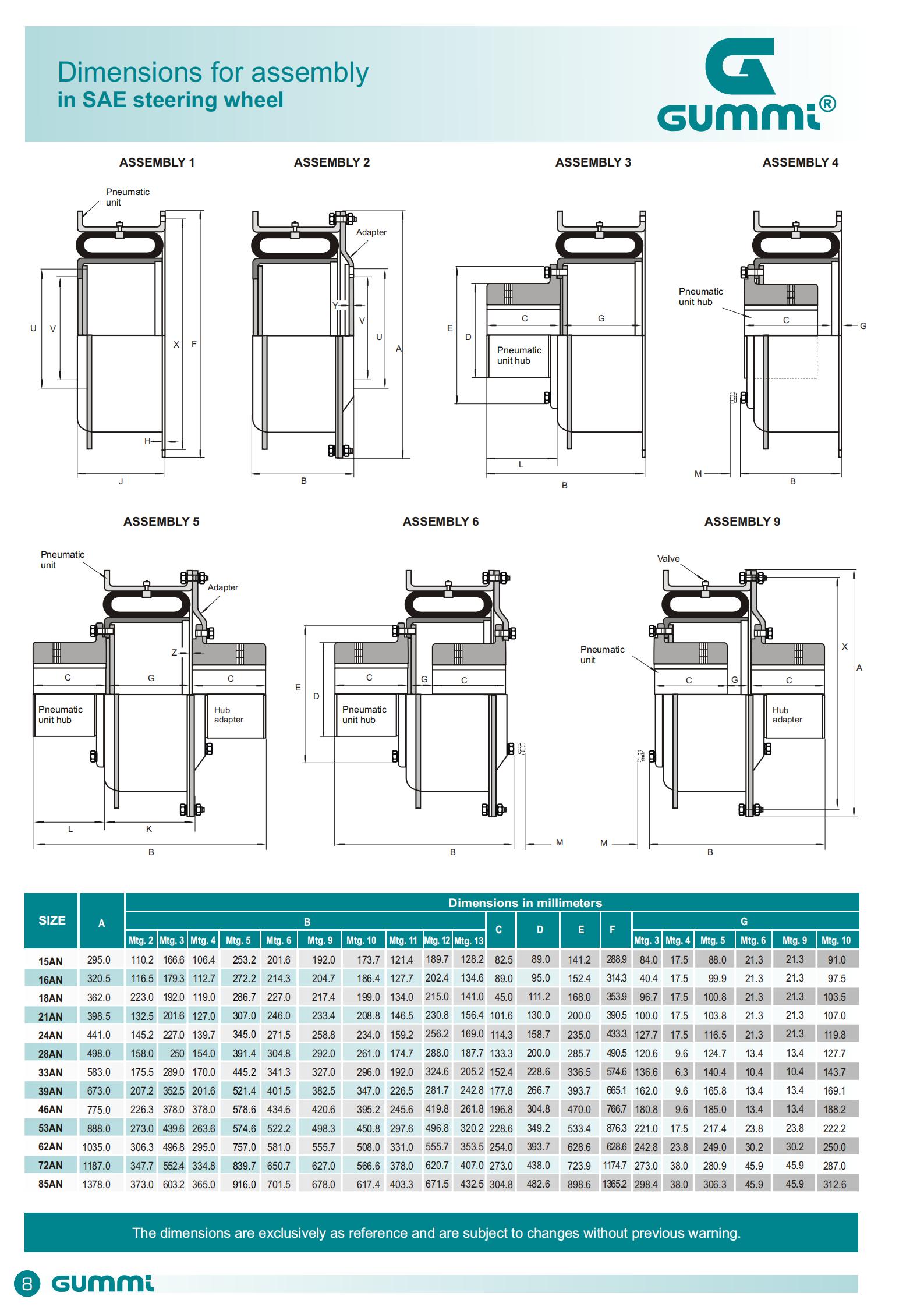

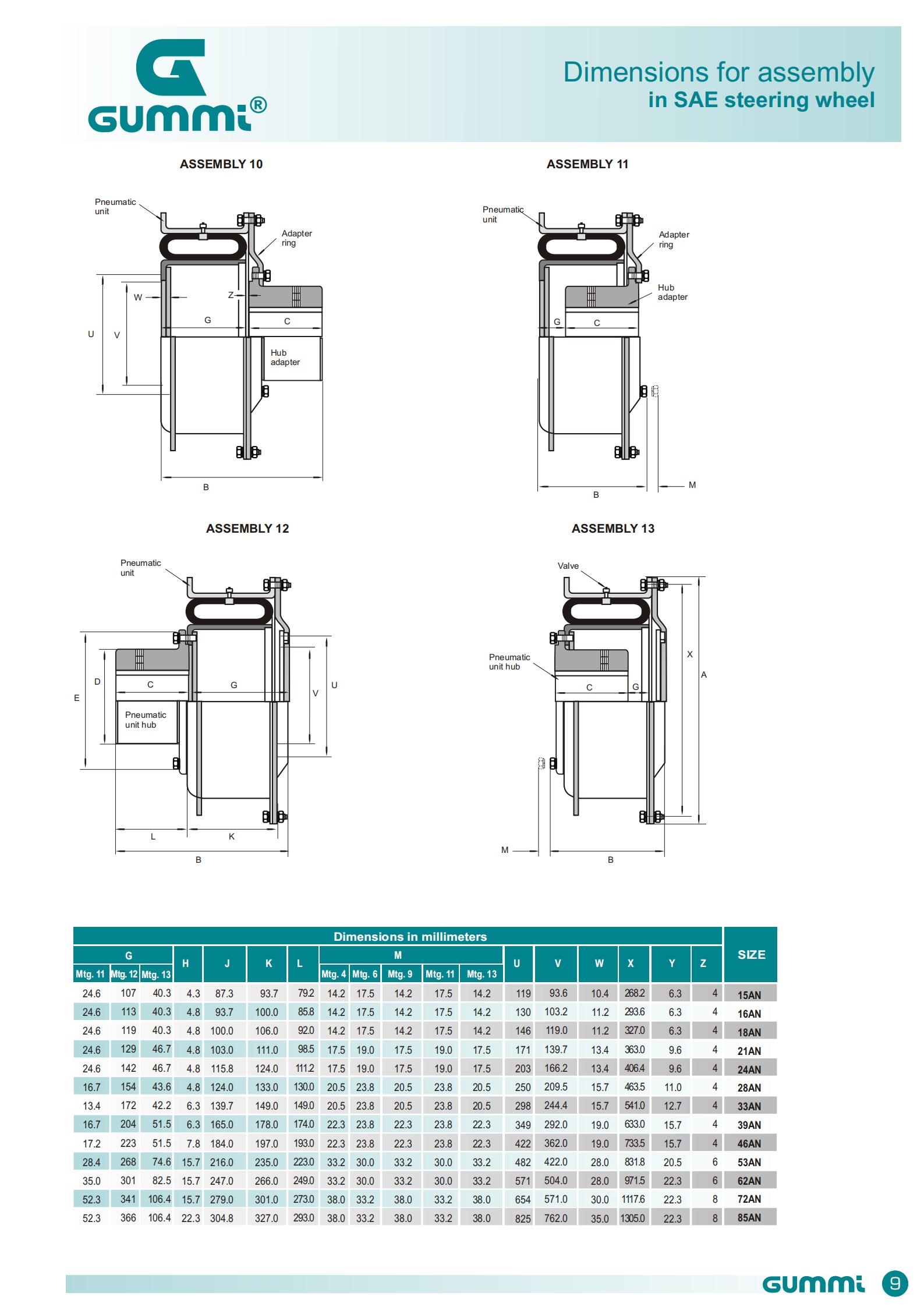

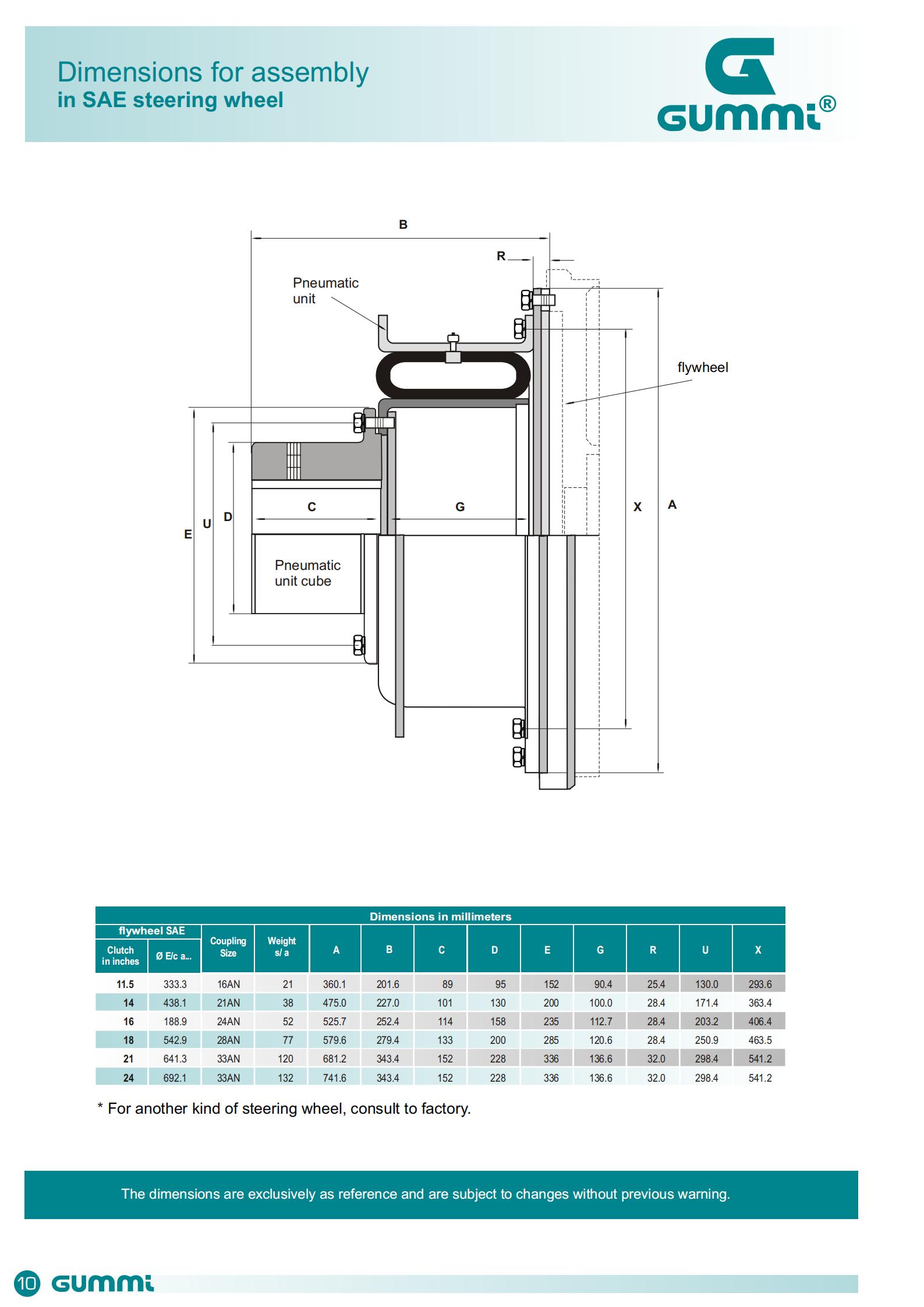

With 13 different assembly configurations and 15 models, including options for flywheel mounting, floating shafts, and dual (tandem) designs, the GUMMI AN couplings offer flexibility for various installation requirements. They are easy to install, requiring no special tools, and support radial, angular, and axial misalignments.Durability and Maintenance

Manufactured under ISO 9001:2000 quality standards, the couplings use only high-grade raw materials. The robust design ensures long-lasting performance, reducing the need for frequent replacements. The natural resilience of the pneumatic rubber chamber provides enhanced durability, helping to dampen shocks and vibrations over time.Model Selection and Configuration

The sizing of the AN coupling depends on the load, power, and speed it must handle. Based on the application, service factors (fs) and "K" factors are used to calculate the basic capacity (CB), which then determines the appropriate coupling size. With 13 standard configurations to choose from, users can select the assembly option that best fits their specific needs, including designs for larger diameter shafts or aggressive environments.Applications:

GUMMI AN couplings are widely used in heavy machinery applications, particularly in internal combustion engines, reciprocating pumps, compressors, and mills. Their versatility makes them suitable for industries such as mining, petroleum, steel, and power generation.Simple Installation & Replacement

The compact design of the GUMMI AN coupling allows for easy alignment and assembly, reducing installation time and effort. Replacements are equally simple, requiring minimal downtime.