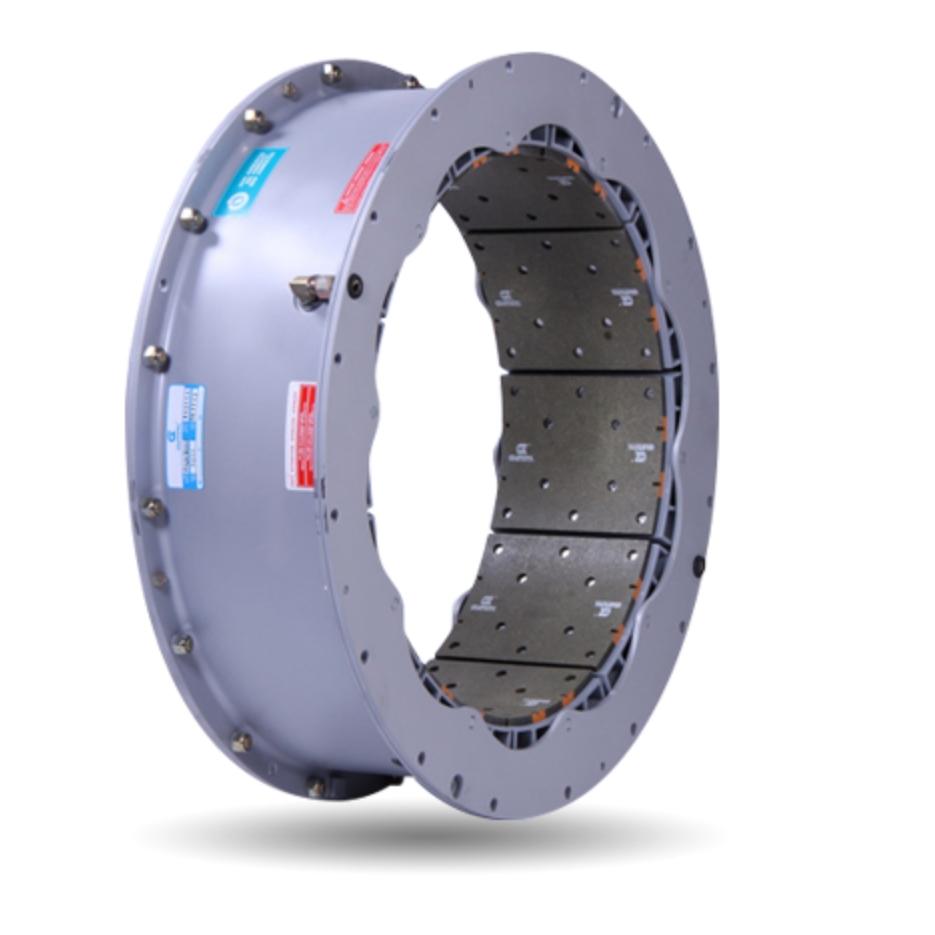

FUMMI FKT Radial Units - pneumatic clutch and brakes

Product Introduction:

The FKT Radial Units are designed for high torque transmission and can withstand large inertial loads and prolonged slippage. The innovative design helps prevent torque loss and extends the product's service life under extreme conditions.

Construction and Design:

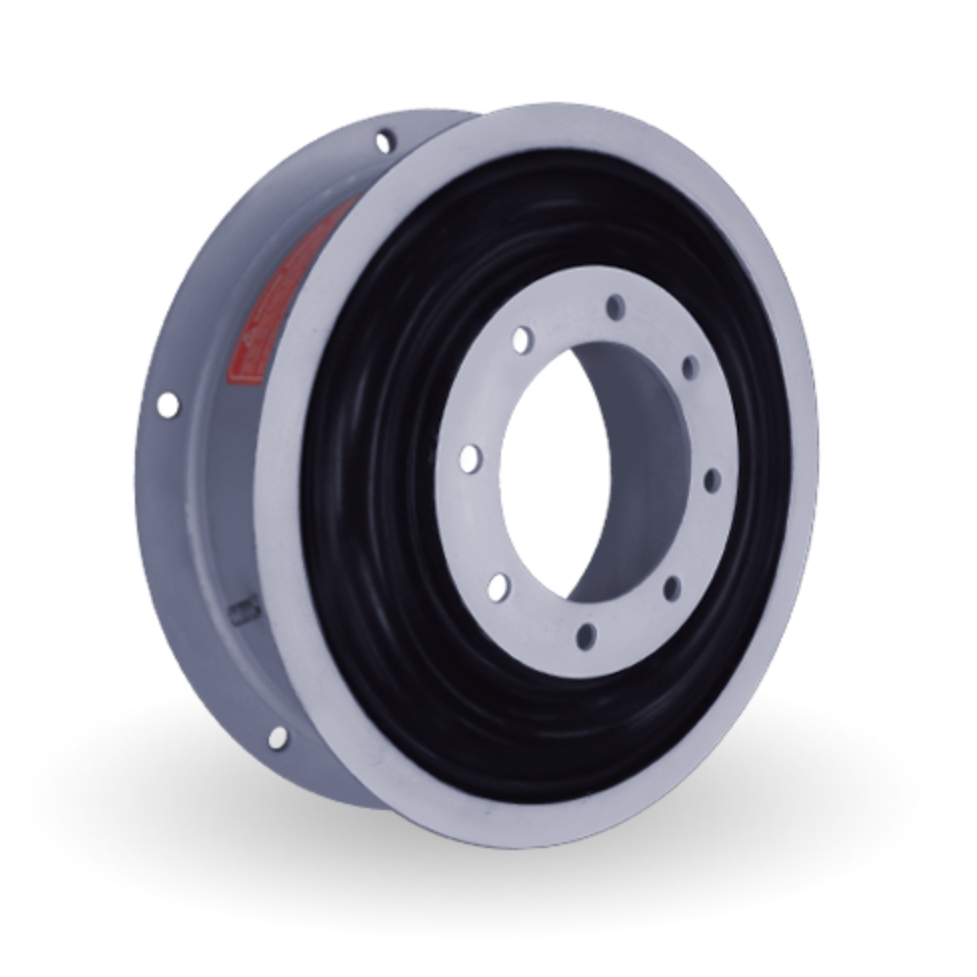

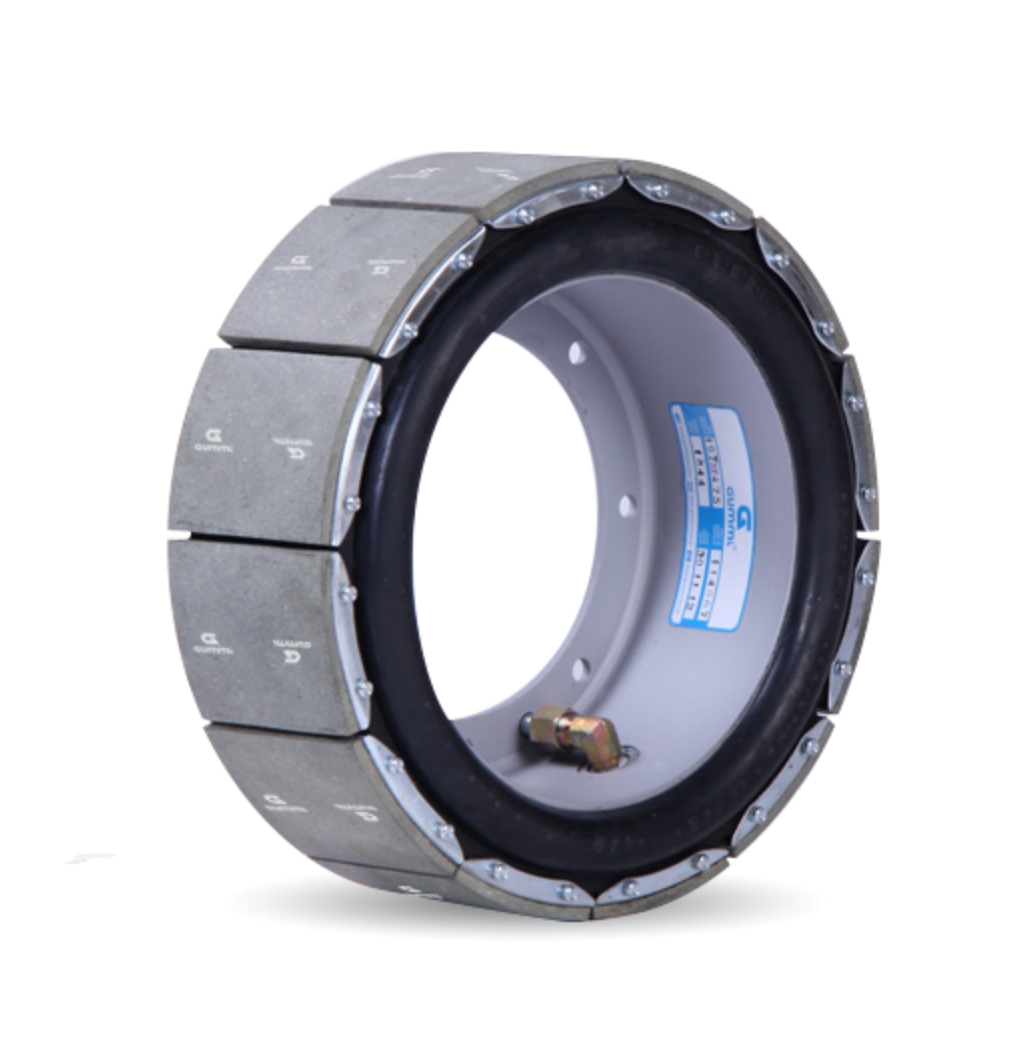

The FKT Radial Units use a torque pin mechanism for transmitting torque, rather than relying on the air chamber's sidewall. This unique design minimizes wear and tear, ensuring longer operational life.Functionality:

These units are equipped with replaceable side plates and are built into a metal ring with a separate air chamber, allowing the clutch or brake to perform reliably under heavy loads. By pressurizing the air chamber, the friction pads apply pressure on the cylindrical drum surface. When the pneumatic element is depressurized, the spring mechanisms pull back the friction pads, disengaging them from the drum.Applications:

The FKT Radial Units are commonly used in industries such as oil, mining, and marine. Their ability to handle heavy inertial loads and extended slippage makes them ideal for heavy-duty industrial applications.Customization:

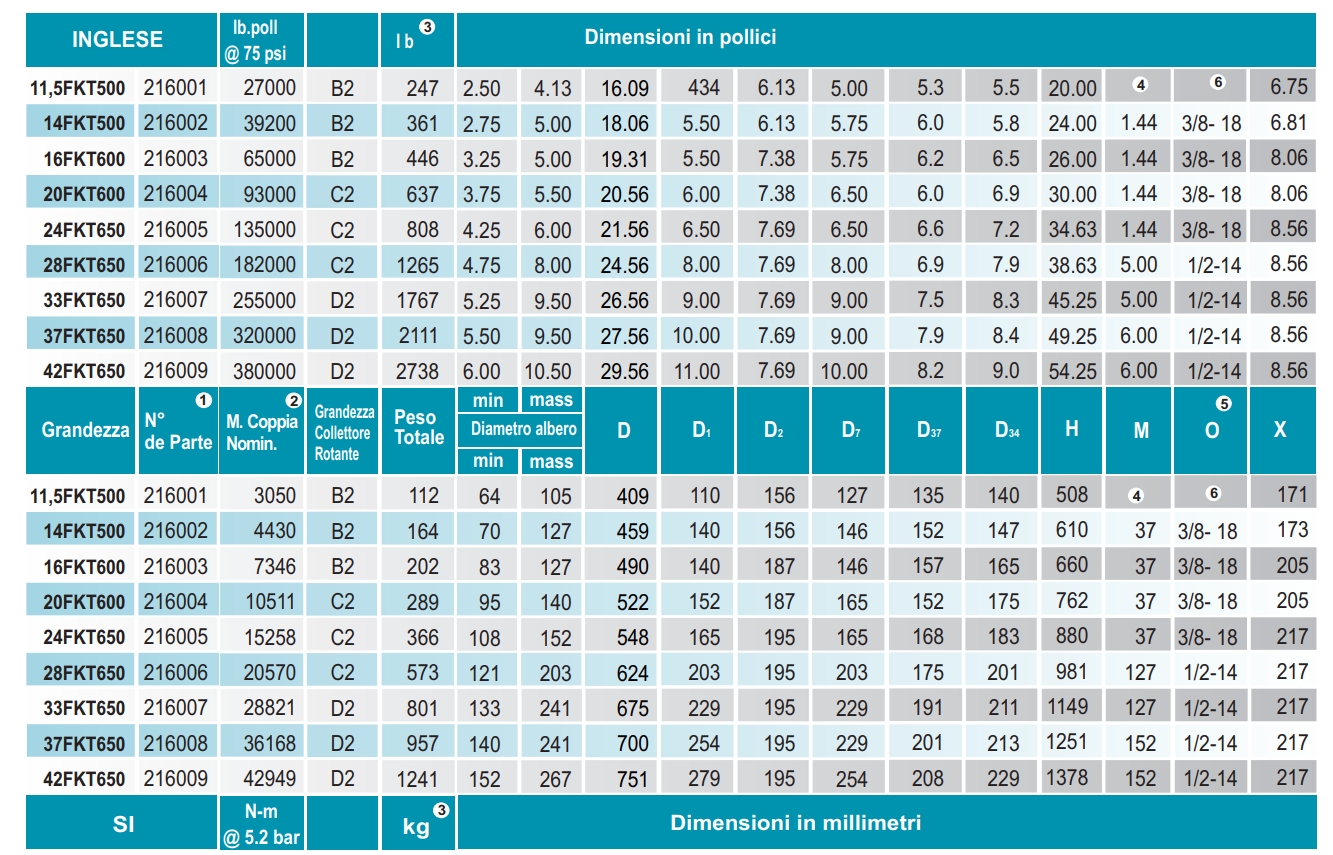

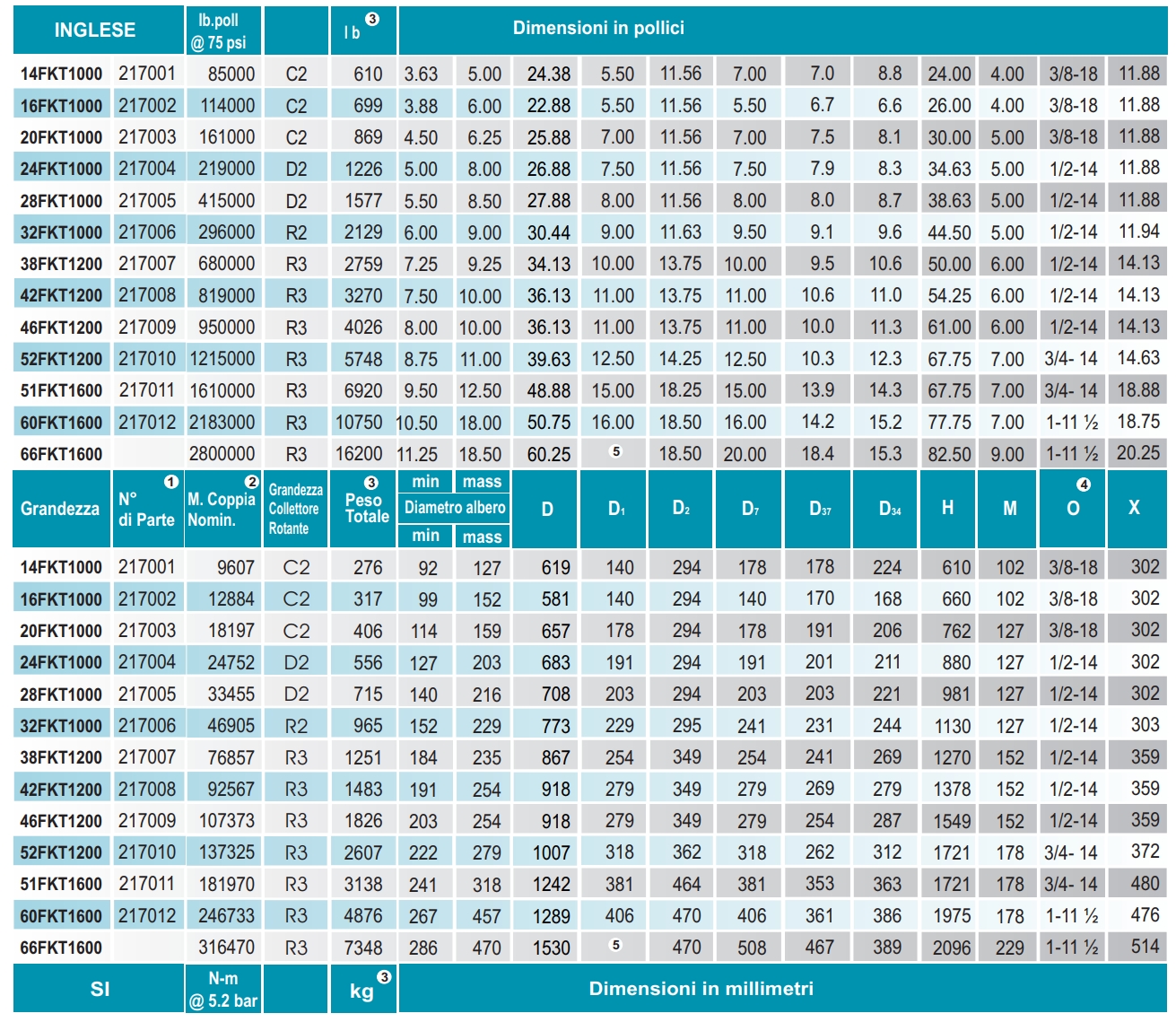

Available in both narrow and wide series, the units can be customized to fit different drum diameters and widths (from 11.5" to 66"), ensuring compatibility with various systems. Whether single or dual, these units can be tailored to meet specific application requirements.Pressure and Torque:

The maximum recommended pressure for these units is 8.6 bar (125 psi), and they operate with a wide torque range between 3050 Nm to 632940 Nm depending on the size and configuration.