GUMMI FKE Pneumatic Elements for Low-Speed Applications

Product Description:

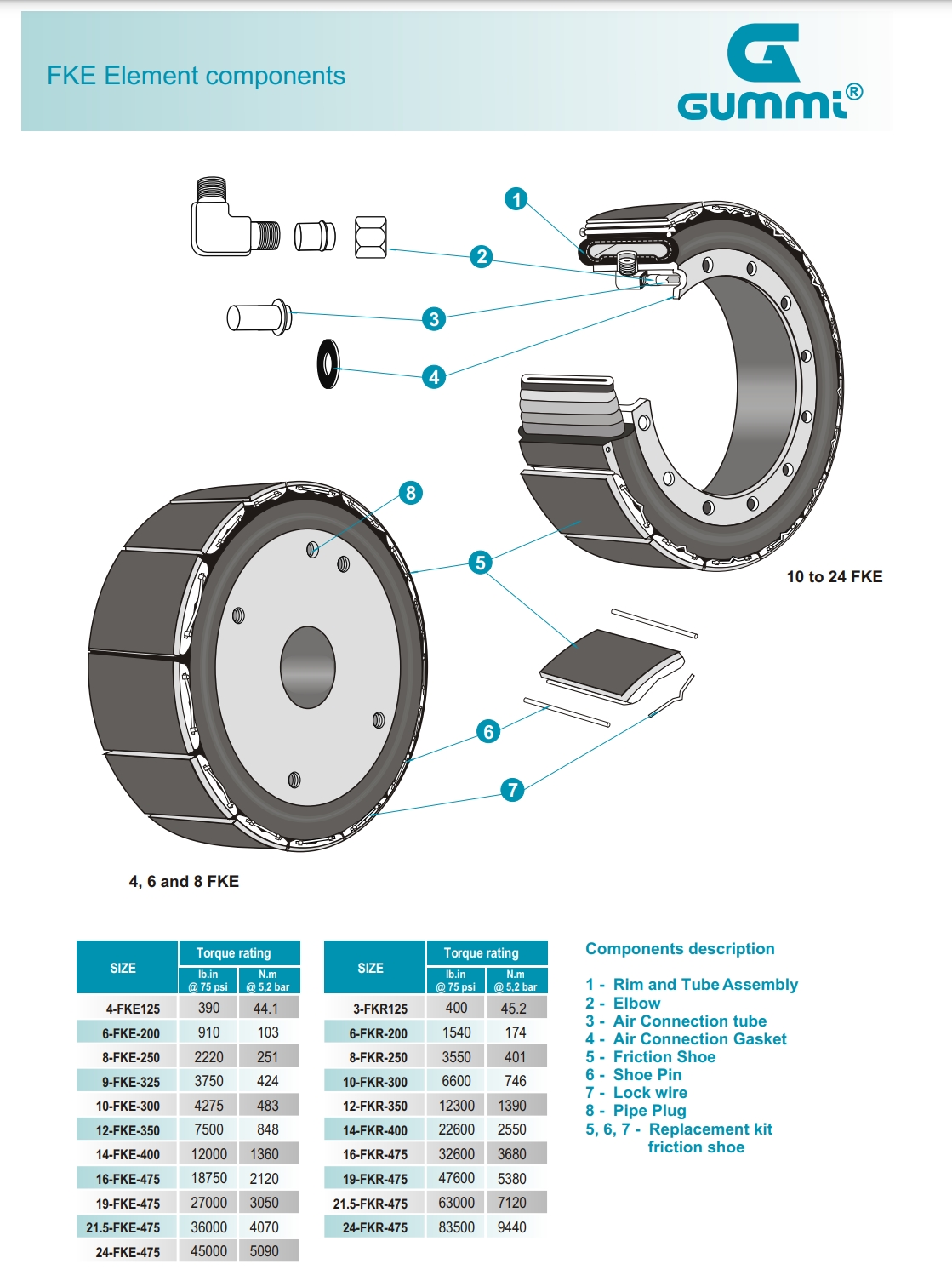

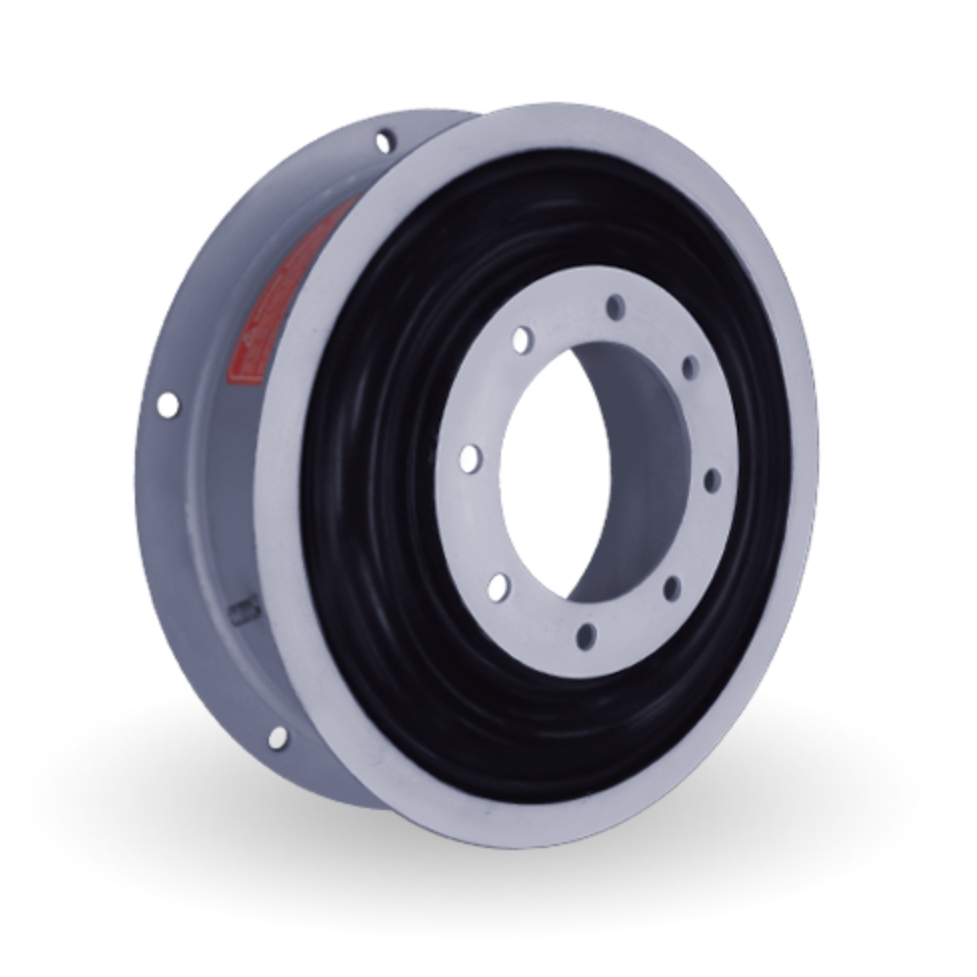

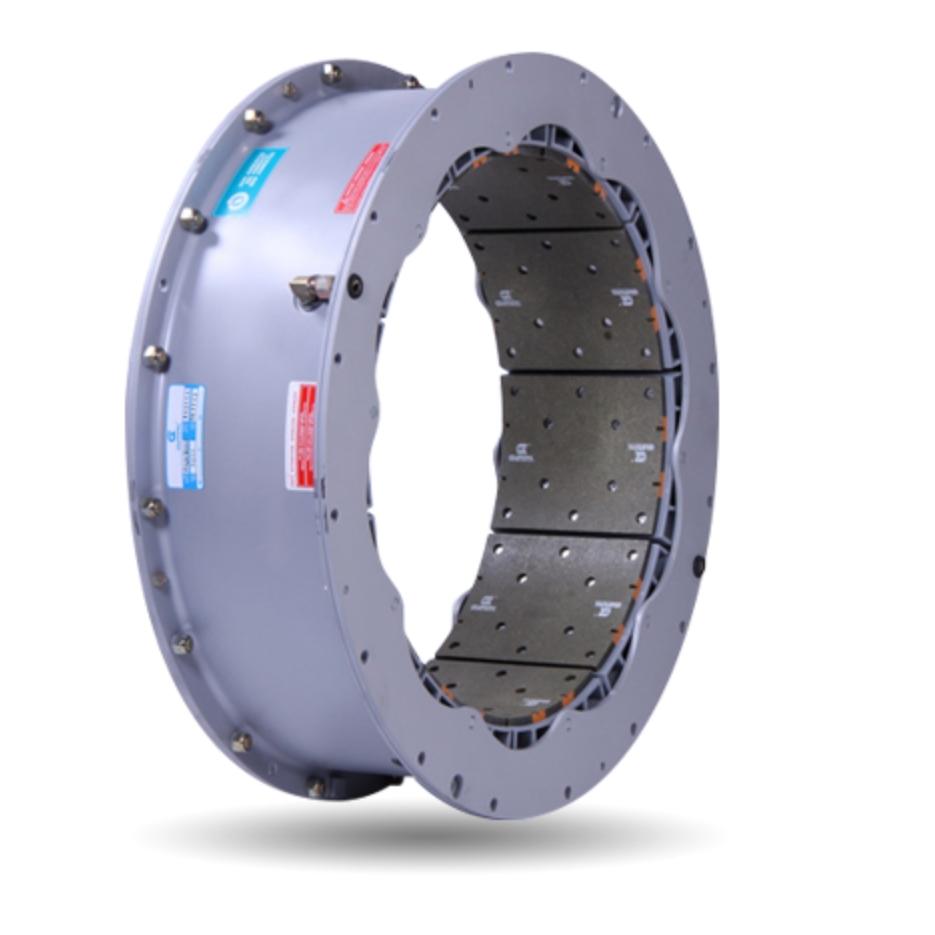

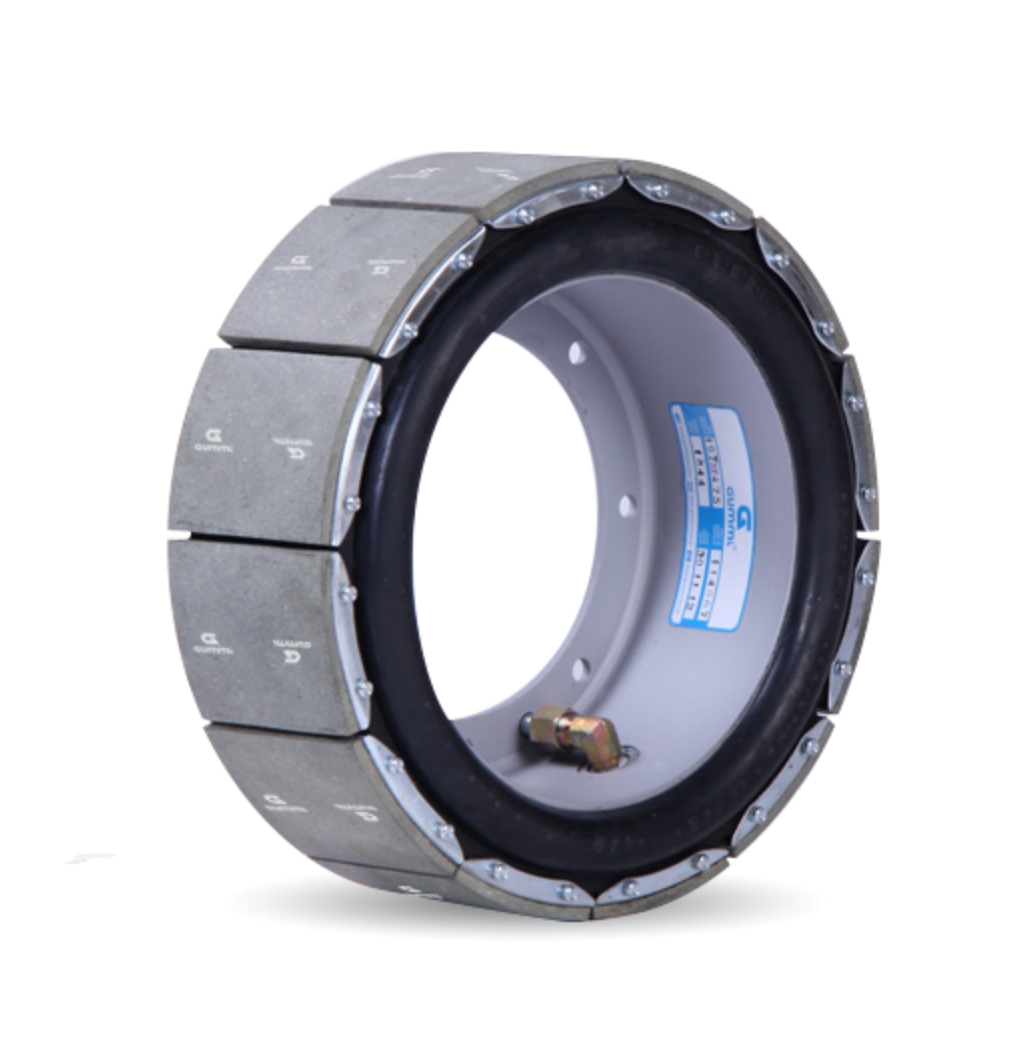

The GUMMI FKE pneumatic elements are designed for low-speed applications, providing smooth starting and stopping loads. These elements function as slip clutches and tensioning brakes, similar in design to the FK elements. Their unique expanding friction design enables them to operate as centrifugal clutches. Made with a reinforced neoprene rubber tube vulcanized to the outer part of a steel rim, the FKE elements deliver efficient torque transmission. When pressurized, the friction shoes expand, engaging the inside diameter of the drum for smooth operation.

Smaller FKE models feature a solid hub, allowing direct shaft mounting, while larger sizes are attached to the shaft via a separate element hub. The FKE series ensures reliable performance in demanding industrial environments, including applications like tension control, braking, and speed regulation.

Key Features:

- Ideal for low-speed applications, smooth start/stop loads, and cyclic operations.

- Expanding friction shoe design with centrifugal clutch functionality.

- Neoprene tube reinforced with cord plys for enhanced durability and performance.

- Torque transmission depends on applied air pressure and speed.

- Available in 11 sizes, identified by the drum’s inner diameter and friction lining width.

- Smallest size works on a 4-inch drum, and the largest on a 24-inch drum.

Performance Data (at 75 psi / 5.2 bar):

| Model | Max Torque (lb.in) | Max Speed (RPM) |

|---|---|---|

| 9FKE325 | 3750 | 1800 |

| 10FKE300 | 4275 | 1800 |

| 12FKE350 | 7500 | 1800 |

| 14FKE400 | 12000 | 1500 |

| 16FKE475 | 18750 | 1300 |

| 19FKE475 | 27000 | 1100 |

| 21FKE475 | 36000 | 1000 |

| 24FKE475 | 45000 | 900 |

Torque Values in SI (at 5.2 bar):

| Model | Max Torque (Nm) | Max Speed (RPM) |

|---|---|---|

| 9FKE325 | 424 | 1800 |

| 10FKE300 | 484 | 1800 |

| 12FKE350 | 848 | 1800 |

| 14FKE400 | 1356 | 1500 |

| 16FKE475 | 2120 | 1300 |

| 19FKE475 | 3050 | 1100 |

| 21FKE475 | 4070 | 1000 |

| 24FKE475 | 5090 | 900 |

Applications:

The FKE elements are perfect for low-speed applications, such as:

- Tensioning brakes

- Slip clutches

- Centrifugal clutches in industrial machinery

These elements are widely used in industries like laundry, pulp and paper, textile, tire fabrication, and marine operations.