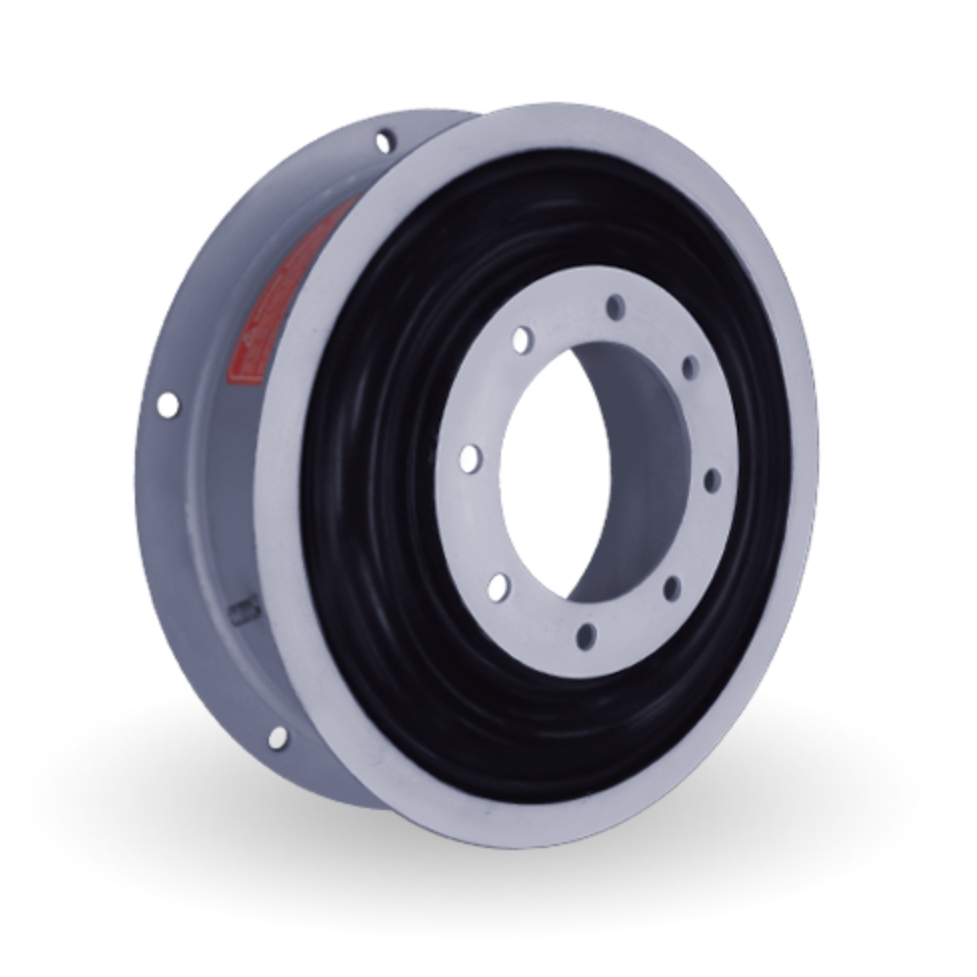

Gummi FKR Elements High Torque Shaft Couplings

FKR Rubber Elements – High Torque Couplings and Holding Brakes

Product Description

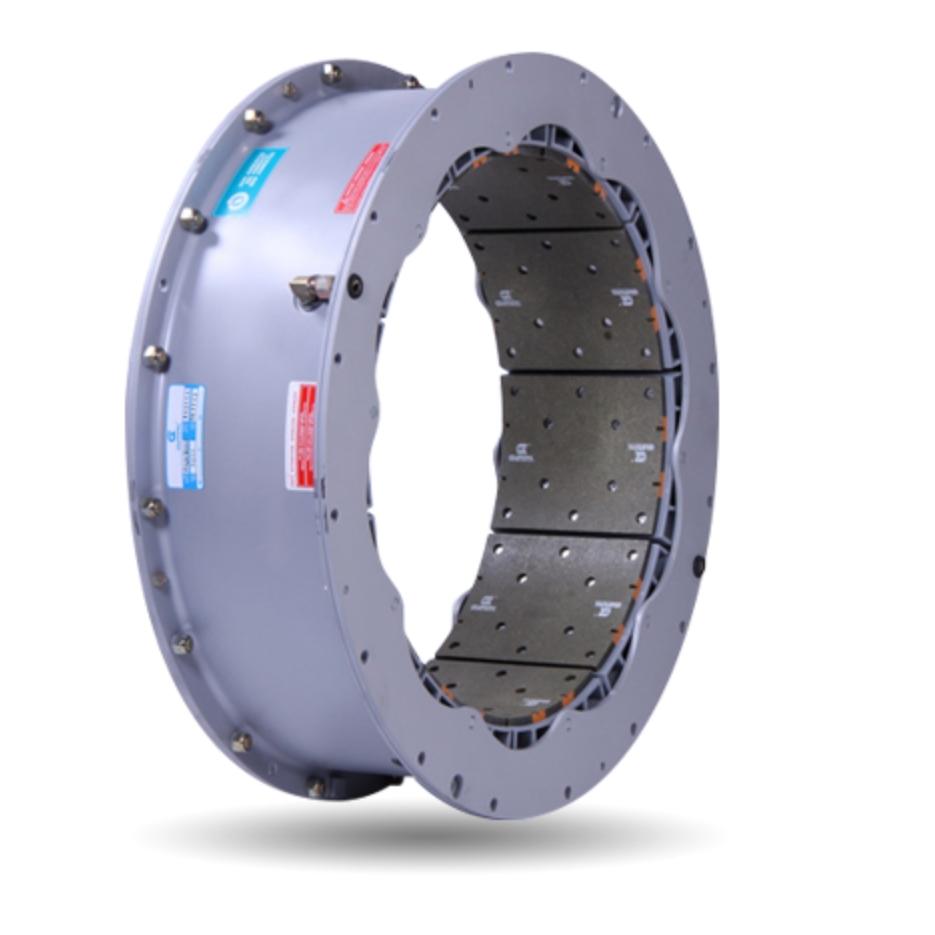

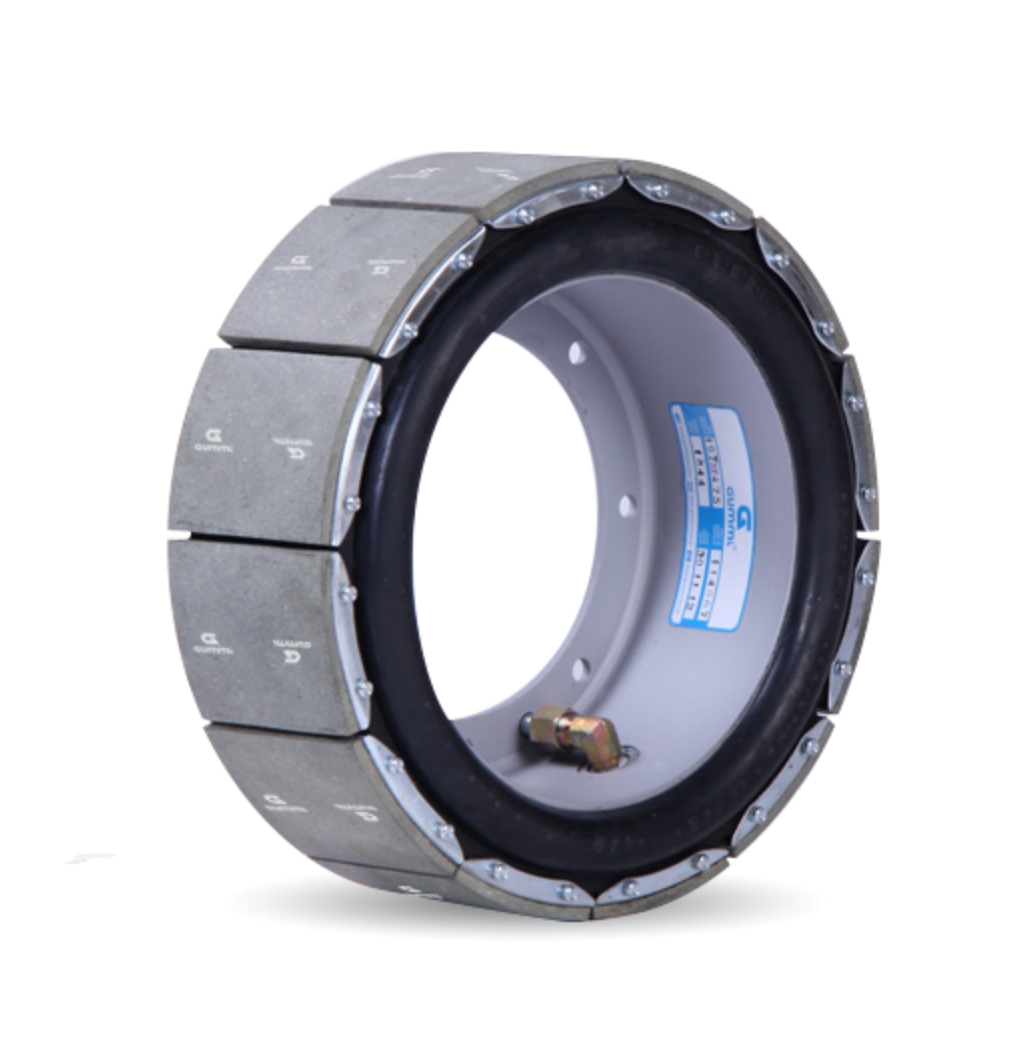

The FKR elements are designed to provide high torque transmission and serve as couplings or holding brakes in specific industrial applications such as laundries, pulp and paper factories, textile industries, tire fabrication, and marine sectors. The key feature of these elements is their ability to provide electrical insulation between the connected shafts while transmitting torque directly through the outer surface of the tube. This design allows disconnection without stopping the primary motion and facilitates cyclical connections between shafts.

Key Features:

- Main function: High torque transmission, used as couplings and holding brakes.

- Electrical insulation: FKR elements provide insulation between connected shafts.

- Torque range: From 45 Nm to 18,880 Nm, covering a wide range of applications.

- Size variety: Available in various sizes from 3" to 24", fitting different drum diameters.

- Radial expanding design: The pneumatic tube expands, activating friction shoes that engage the drum to transmit torque.

Benefits:

- Ideal for applications where disconnection must be done without stopping primary motion.

- Suitable for applications where the speed differential between shafts must be zero.

- Commonly used as couplings for torque transmission and as holding brakes in various industries.

Size and Torque Capacity:

The FKR elements are available in 10 different sizes. The smallest models operate on drums with an inner diameter of 3" (76 mm), and the largest on drums with an inner diameter of 24" (610 mm). The smallest size does not have replaceable friction shoes as they are vulcanized directly to the tube. The torque transmission capacity depends on the applied air pressure, with values indicated at 75 psi (5.2 bar) and zero RPM.

Applications:

- Textile Industry

- Tire Fabrication

- Marine Industry

- Pulp and Paper Industry

- Industrial Laundries

The FKR elements are ideal for applications where disconnection must be performed without stopping primary motion and for frequent connections between driving and driven components.

Product Details:

The FKR elements transmit torque through the outer surface of the tube and offer electrical insulation between shafts, making them ideal for applications where the speed differential between shafts must be zero. Available in a variety of sizes, FKR elements are used in sectors such as textile, tire fabrication, marine, pulp and paper, and industrial laundries.

- Torque range: 45 Nm to 18,880 Nm

- Available sizes: 3" to 24"

- Provides electrical insulation

- Radial expanding pneumatic tube design

The FKR elements are designed to be used in applications where frequent disconnection of components is required. With high torque density and the ability to transmit power without stopping motion, they are particularly well-suited for use in industrial environments where reliability is essential.